pozsar

- 1

- 0

- TL;DR

- searching for pre manufactured radiator suitable for airflow from the 'side surface'

Hi everyone!

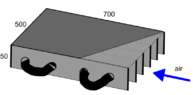

I'm doing a DIY project in which I have to use air cooling to regulate water temperatures of max 90°C. I want to use some cheap (possibly even used) pre-manufactured radiator to do the job for me (since I'm unable to make finned pipes with tight enough fittings to provide sufficient heat conduction between the tube and sheets), but I have environment constraints that make it impossible to channel the air through the largest surface like automotive radiators do (pic 1). I have to direct air through the 'side surface' (pic 2). I simply need long parallel aluminum sheets with tubes going through them. The dimensions of the radiator are planned to be roughly 50x500x700mm and the inner diameter of the tube should be ~10mm. I have been searching through the internet for days, but I'm not happy with my results. The best match at the moment is some oil cooler radiator which I find unnecessarily high in quality for my application (pic 3).

How can I find a radiator that is suitable for this? In what field do they use such radiators?

I'm doing a DIY project in which I have to use air cooling to regulate water temperatures of max 90°C. I want to use some cheap (possibly even used) pre-manufactured radiator to do the job for me (since I'm unable to make finned pipes with tight enough fittings to provide sufficient heat conduction between the tube and sheets), but I have environment constraints that make it impossible to channel the air through the largest surface like automotive radiators do (pic 1). I have to direct air through the 'side surface' (pic 2). I simply need long parallel aluminum sheets with tubes going through them. The dimensions of the radiator are planned to be roughly 50x500x700mm and the inner diameter of the tube should be ~10mm. I have been searching through the internet for days, but I'm not happy with my results. The best match at the moment is some oil cooler radiator which I find unnecessarily high in quality for my application (pic 3).

How can I find a radiator that is suitable for this? In what field do they use such radiators?