LT72884

- 335

- 49

Hello all, I am using an open source software called openFAST, and it shows various outputs such as the force along the x axis as the blade rotates around.

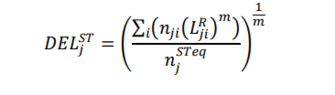

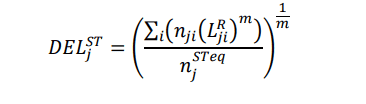

I then use a python script that uses the following equation:

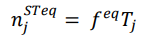

where:

and feq = 2.1Hrz for my example and T is 60 seconds

This is what is called Damage Equivalent Load, but im not sure what that actually means? Equivalent to what? What exactly is DEL? is it based off of cycles or something?

thanks

I then use a python script that uses the following equation:

where:

and feq = 2.1Hrz for my example and T is 60 seconds

This is what is called Damage Equivalent Load, but im not sure what that actually means? Equivalent to what? What exactly is DEL? is it based off of cycles or something?

thanks