Venkata Satish

- 10

- 0

Thanks for your reply. Now i agree that no extra energy is generated.

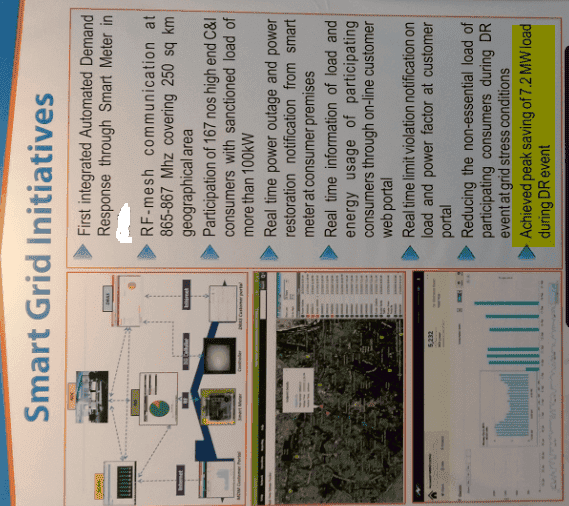

But recently i went to a conference. They put these statement like "Achieved peak savings of 7.2 MW load during DR (Demand Response) Event"

What do they mean by peak savings of 7.2 MW mean? If Produced energy is same as consumed energy where is the saving? Is is commercial savings they are talking about? Meaning they committed to purchase more power but now they reduced it to 7.2 MW because of Demand Response?

Sorry one more question. If utility orders Energy say tomorrow we want 1000MW, are they obligated to buy even thought they have supplied less because of consumption?

But recently i went to a conference. They put these statement like "Achieved peak savings of 7.2 MW load during DR (Demand Response) Event"

What do they mean by peak savings of 7.2 MW mean? If Produced energy is same as consumed energy where is the saving? Is is commercial savings they are talking about? Meaning they committed to purchase more power but now they reduced it to 7.2 MW because of Demand Response?

Sorry one more question. If utility orders Energy say tomorrow we want 1000MW, are they obligated to buy even thought they have supplied less because of consumption?