gaus12777

- 12

- 1

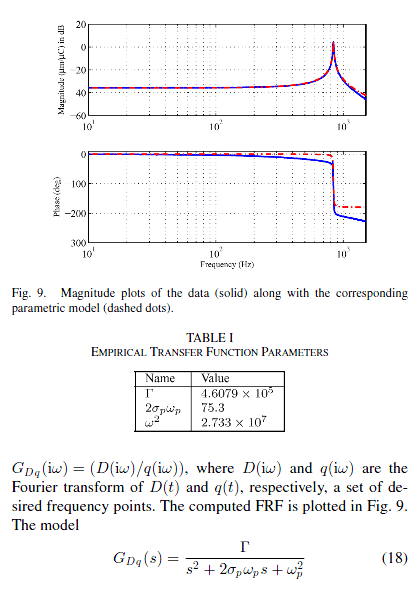

I have drawn a bode plot(freauency response), but it is not the same with one which is attatched in paper.

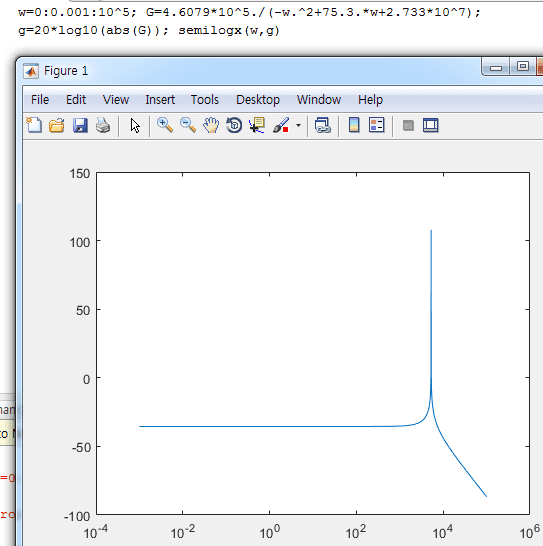

Using this data, I have drawn the graph using matlab.

I just put data into second order vibratoion system which is given in the paper(eq 18)

Peak location of graph in paper is just in front of 10^3 but the other is just in front of 10^4.

What is wrong?

Using this data, I have drawn the graph using matlab.

I just put data into second order vibratoion system which is given in the paper(eq 18)

Peak location of graph in paper is just in front of 10^3 but the other is just in front of 10^4.

What is wrong?