mazzo532

- 7

- 0

- TL;DR

- Why does my sensor shows "gaps" every 16 units of resolution? SEE IMAGE

Hello Gentlemen,

I'm not an EE engineer, yet trying to help my colleagues. I would like to get a general feeling of what could be going on.

Probably trivial for some of you.

Background

We have a motor/torque sensor device that is measuring torque values. We get out digital signals for Torque and Position.

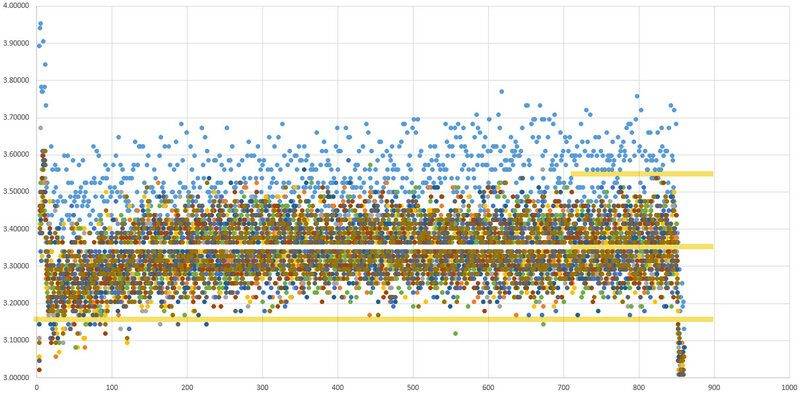

Below you can find a simple plot of a bunch of torque curves (several repetitions of the same experiment).

Plots are simply Torque vs sampling point count.

Question/issue

As you can notice from the the torque curves, there seems to be torque values that are "not used" by our sensor. Empty bands, no matter what.

I could define them as "gaps in the measurement resolution".

The only remarkable detail is that I seem to see 1 "resolution gap" every 16 resolution points exactly.

In other words, if resolution was 0.1Nm our measurement system would acts like this:

1. Can measure 0.0Nm

2. Can measure 0.1Nm

3. Can measure 0.2Nm

...

15. Can measure 1.4Nm

16. GAP --> Cannot measure 1.5Nm

...

and so onI have the feeling this phenomenon is super trivial

What could that be?

What are good keywords to search info about such a phenomenon in the web?I'm sorry for the basic formulation. Any hint appreciated.

Thank you in advance!

I'm not an EE engineer, yet trying to help my colleagues. I would like to get a general feeling of what could be going on.

Probably trivial for some of you.

Background

We have a motor/torque sensor device that is measuring torque values. We get out digital signals for Torque and Position.

Below you can find a simple plot of a bunch of torque curves (several repetitions of the same experiment).

Plots are simply Torque vs sampling point count.

Question/issue

As you can notice from the the torque curves, there seems to be torque values that are "not used" by our sensor. Empty bands, no matter what.

I could define them as "gaps in the measurement resolution".

The only remarkable detail is that I seem to see 1 "resolution gap" every 16 resolution points exactly.

In other words, if resolution was 0.1Nm our measurement system would acts like this:

1. Can measure 0.0Nm

2. Can measure 0.1Nm

3. Can measure 0.2Nm

...

15. Can measure 1.4Nm

16. GAP --> Cannot measure 1.5Nm

...

and so onI have the feeling this phenomenon is super trivial

What could that be?

What are good keywords to search info about such a phenomenon in the web?I'm sorry for the basic formulation. Any hint appreciated.

Thank you in advance!