- #1

KiNGGeexD

- 317

- 1

Question;

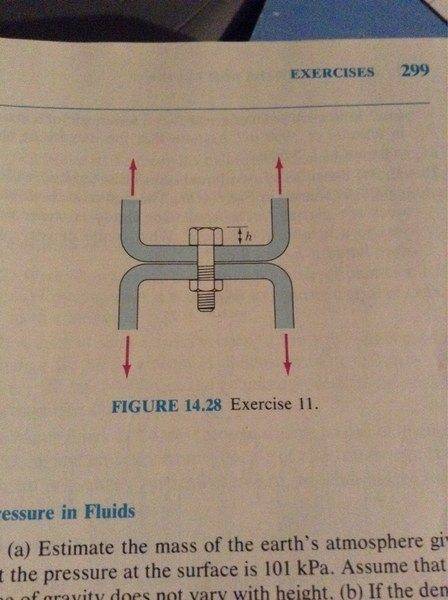

The shank of the bold has a diameter of 1.2cm and a head height of 0.8cm. What is the maximum tensile load that the bolt can withstand if it's ultimate shear strength is 3.5*10^8 N/m^2I have attached a photo of the diagram given in the question.My attempt

I noticed that this is a question about shear modulus and could easily compute the force but the only thing I don't have in order to do so is the change in x? Any help would be fantastic I should say this is merely a practice textbook question and not an assignment or anything:) cheers again!

Oh and the answer given was 1.06*10^4 N :):)

The shank of the bold has a diameter of 1.2cm and a head height of 0.8cm. What is the maximum tensile load that the bolt can withstand if it's ultimate shear strength is 3.5*10^8 N/m^2I have attached a photo of the diagram given in the question.My attempt

I noticed that this is a question about shear modulus and could easily compute the force but the only thing I don't have in order to do so is the change in x? Any help would be fantastic I should say this is merely a practice textbook question and not an assignment or anything:) cheers again!

Oh and the answer given was 1.06*10^4 N :):)