- #1

Stormer

- 113

- 22

- TL;DR Summary

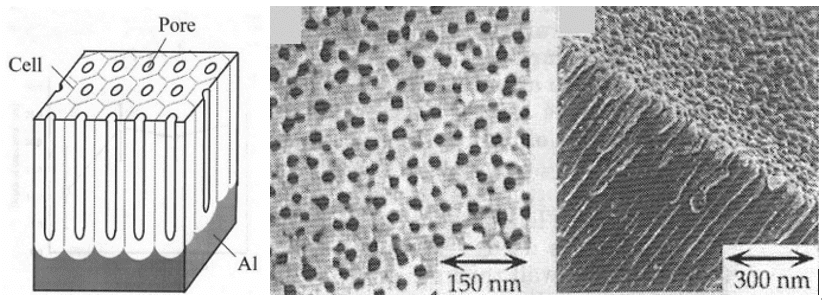

- Using Aluminium anodizing pores as filter membrane.

When anodizing aluminium (or Titanium) a dense hexagonal pattern of microscopic pores is formed, and you can get a pretty high aspect ratio with them. But the illustrations always show the oxide layer with pores on top of a pure aluminium layer. But can you oxidize a thin sheet of material so that the pores go all the way trough so you can use this as a sort of filtering membrane? And if so how thin of a sheet do you need to use? Or can you use a enchant that etch the pure aluminium away, but don't etch the oxide layer?