- #1

berdan

- 32

- 0

Hi Guys, please please assist me!

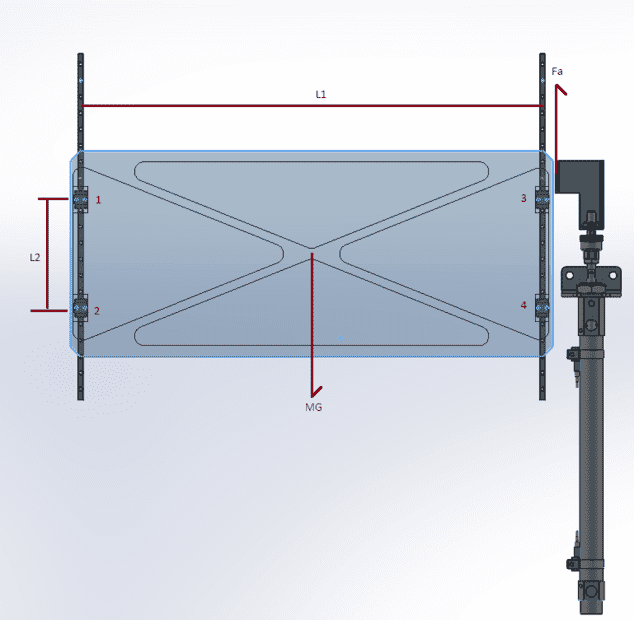

I need to pick for a project at my work linear carriages which should work at this configuration :

As you can see, there is a piston which moves the plate on 4 bearings from the side (yes, I know, not the best configuration, but that's what we have given the spatial constraints).

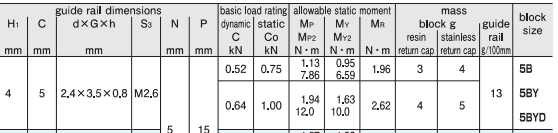

From looking at manufacturer site for linear bearings, I can see that the parameter I need to calculate is Static Load C0, given in Newtons.

(BTW we built that system already, and we have a "caging", in a lack of better word. When system starts moving, one side with bearing 3 & 4 goes up before 1 & 2, and then that's it. No more movement because of that tilt).

So,Static Load C0, that's what I should calculate? Then why there are three moment parameters at manufacturer site (allowable moments) ?

Should I calculate those moments as well ? How the hell do I solve that issue ? Please assist, I'm getting nuts here.

I need to pick for a project at my work linear carriages which should work at this configuration :

As you can see, there is a piston which moves the plate on 4 bearings from the side (yes, I know, not the best configuration, but that's what we have given the spatial constraints).

From looking at manufacturer site for linear bearings, I can see that the parameter I need to calculate is Static Load C0, given in Newtons.

(BTW we built that system already, and we have a "caging", in a lack of better word. When system starts moving, one side with bearing 3 & 4 goes up before 1 & 2, and then that's it. No more movement because of that tilt).

So,Static Load C0, that's what I should calculate? Then why there are three moment parameters at manufacturer site (allowable moments) ?

Should I calculate those moments as well ? How the hell do I solve that issue ? Please assist, I'm getting nuts here.