- #1

- 9,832

- 4,894

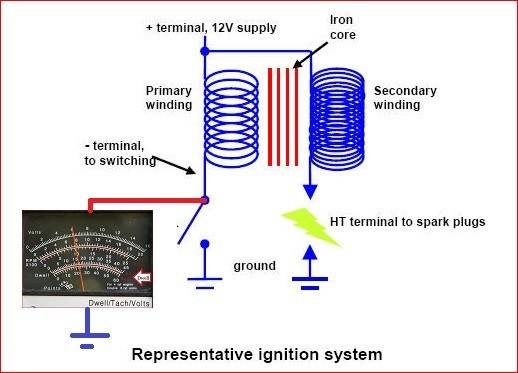

In the days of points everybody used a Dwell Meter to check their points gap setting.

Even this old PF thread is vague as to meaning of "dwell" as regards coil charge time.

https://www.physicsforums.com/threads/dwell-time.64011/

The original Kettering patent used term "dwell" in another sense, namely points closed when engine is stopped which would run down the battery.

https://www.google.com/patents/US1223180

He included a temperature sensitive iron wire to reduce coil current when points stay closed too long, sort of a 1912 PTC thermistor. It doubtless evolved to the ballast resistor we all knew and loved in the 1960's.

Nowadays "Dwell" is defined as fraction of the time points stay closed, ie coil charging time expressed as degrees of camshaft rotation.

It's just a voltmeter connected across the points EDIT Later i found this was a bad assumption on my part , read on..

points closed = no voltage

points open = battery voltage (12 volts)

so, more time the points are open = more voltage = increasing meter indication

0 volts = points always closed = coil energized 100% of the time

12 volts = points always open = coil energized 0% of the time

If full scale indication = battery voltage 12 volts = points always open, coil energized 0 % of the time

AND that agrees with the right hand end of the scale - a six lobe cam would be 60 degrees between lobes , meaning 60 degrees indicated dwell says points are open for the entire 60 degrees between cylinders and the engine ought not run because there's no time left to charge the coil between cylinders - the points never close.

so i think there's widespread confusion afoot.

I think a dwell meter reports not the number of camshaft degrees points are closed charging the coil,

instead it reports the number of camshsft degrees the points are open between charging intervals.

Despite what's written all over the internet.

EDIT Atleast some dwell meters report correctly, as i found in post further down. Next line is wrong,too .

Setting points for more dwell indication as indicated by a dwell meter will hurt high speed performance because it shortens coil charge time.

Next time you have your dwell meter out, put a 9 volt battery across it and see what it reads ?

I think it will read about ¾ scale, EDIT retracted, see further down

which is 45 degrees on 6 cylinder scale or 33.75 degrees on4 oops make that 8 cylinder scale.

Then check carefully - does widening the point gap make your dwell meter read more dwell angle , or less ?

I think the scale on dwell angle meters is backward. I'd love to know where i went wrong.

EDIT

In one case i found a dwell meter with scale printed in reverse which corrects the error, a few posts down

I suspect most but not all read correctly. Also found two with active internal electronics to make them report correctly.

old jim

Even this old PF thread is vague as to meaning of "dwell" as regards coil charge time.

https://www.physicsforums.com/threads/dwell-time.64011/

The original Kettering patent used term "dwell" in another sense, namely points closed when engine is stopped which would run down the battery.

https://www.google.com/patents/US1223180

The resistance coil 24, which may be in the shape illustrated or in any other form is preferably constructed of iron wire, nickel or other metals having a normally low coeflicient of resistance, but thereslstance of which will be increased as the heat or tem perature thereof increases, that is, one of the properties of metals of this character being that they are normally good electrical conductors for current, up to a certain predetermined point, but beyond that polnt, the resistance thereof, materially increases as the temperature of the metals are raised by mechanism has been brought to a stand-still in such position that the circuit is closed thcrethrough, or from other causes, a con tinuous flow of 'current will be set up through the main circuit. If this flow of current is permitted to exist, asis generally the case, in ignition systems now in use, the supply of current contained in the battery or accumulator 20, would be materially reduced within a short time.

He included a temperature sensitive iron wire to reduce coil current when points stay closed too long, sort of a 1912 PTC thermistor. It doubtless evolved to the ballast resistor we all knew and loved in the 1960's.

Nowadays "Dwell" is defined as fraction of the time points stay closed, ie coil charging time expressed as degrees of camshaft rotation.

A logical enough unit, but take a look at what a "Dwell Meter" reports !https://www.collinsdictionary.com/us/dictionary/english/dwell-angle said:( Automotive engineering : Vehicle components , Engine, transmission, and exhaust )

https://www.collinsdictionary.com/us/dictionary/english/dwell angle is the amount of time, measured as https://www.collinsdictionary.com/us/dictionary/english/degree of https://www.collinsdictionary.com/us/dictionary/english/rotation, that https://www.collinsdictionary.com/us/dictionary/english/contact breakers close in a https://www.collinsdictionary.com/us/dictionary/english/distributor.

It's just a voltmeter connected across the points EDIT Later i found this was a bad assumption on my part , read on..

points closed = no voltage

points open = battery voltage (12 volts)

so, more time the points are open = more voltage = increasing meter indication

0 volts = points always closed = coil energized 100% of the time

12 volts = points always open = coil energized 0% of the time

If full scale indication = battery voltage 12 volts = points always open, coil energized 0 % of the time

AND that agrees with the right hand end of the scale - a six lobe cam would be 60 degrees between lobes , meaning 60 degrees indicated dwell says points are open for the entire 60 degrees between cylinders and the engine ought not run because there's no time left to charge the coil between cylinders - the points never close.

I think a dwell meter reports not the number of camshaft degrees points are closed charging the coil,

instead it reports the number of camshsft degrees the points are open between charging intervals.

Despite what's written all over the internet.

EDIT Atleast some dwell meters report correctly, as i found in post further down. Next line is wrong,too .

Next time you have your dwell meter out, put a 9 volt battery across it and see what it reads ?

which is 45 degrees on 6 cylinder scale or 33.75 degrees on

Then check carefully - does widening the point gap make your dwell meter read more dwell angle , or less ?

I think the scale on dwell angle meters is backward. I'd love to know where i went wrong.

EDIT

In one case i found a dwell meter with scale printed in reverse which corrects the error, a few posts down

I suspect most but not all read correctly. Also found two with active internal electronics to make them report correctly.

old jim

Last edited: