- #1

TechTree

- 32

- 10

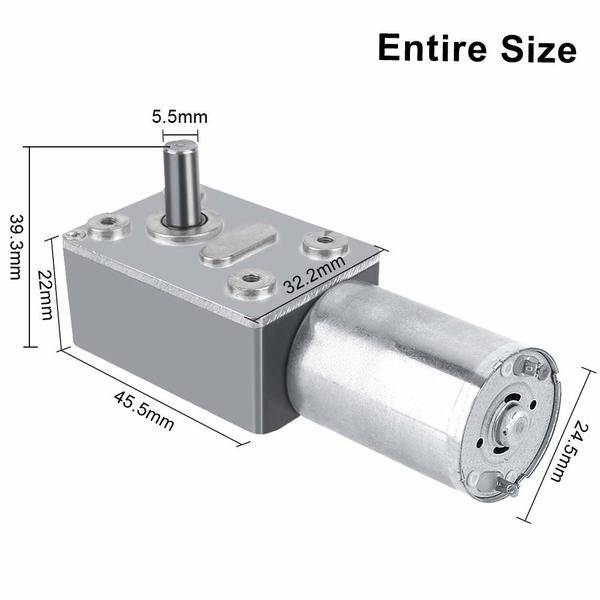

Hello, I'm trying to use this gearbox motor as a winch to lift up a small box (5kg), however it needs to have some sort of drum that's mounted to the motor shaft to wrap the string around. Although I'm unable to find anything suitable that I could use. Is there already something that exists that could work for this, if so how would I go about attaching it to the motor shaft? Here are a few images of the motor:

(Motor Specifications: 12v DC 15 kg.cm)

Any suggestions?

Thanks.

(Motor Specifications: 12v DC 15 kg.cm)

Any suggestions?

Thanks.