- #1

nrobidoux

- 25

- 0

- TL;DR Summary

- Being ambitious at work I had an idea that would help us but lack engineering knowledge. Fluid dynamics: does cross sectional area differ between these two objects?

Because my little work project involves fluids I thought this the best topic to post under.

I took the route of biological sciences and computer science. This area is out of my league at the moment I'm not sure the amount of time that would be required to get the material applicable to this.

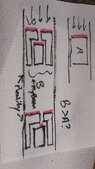

The question is pretty simple. There's a 4" I.D. steel tube with water flowing through at ~12mph. There is a choice between two cylinders. Both diameters are 3.8"; both appear similar externally except the top/bottom of #2. One is solid. The other has a 0.5" inlet on top which leads to another cylindrical solid. The outlet has more cross sectional area than the inlet.

Will each perform identically or will the latter be more effective? ("Grab more" water)

Ascii art not the easiest on the phone, my thinking got me here mathematically:

Cylinder A X- sectional area = 1.9^2 * pi

Cylinder B's =

(1.9^2 * pi - 0.25^2 * pi) + (1^2 * pi)

i.e. 3.8" top with 0.5" inlet to 2" Cylinder beneath

Have no idea if B is correct... or leaning towards the correct idea. (2nd term effectively multiplied by coefficient < 1 but result > the cross sectional area of inlet)

I took the route of biological sciences and computer science. This area is out of my league at the moment I'm not sure the amount of time that would be required to get the material applicable to this.

The question is pretty simple. There's a 4" I.D. steel tube with water flowing through at ~12mph. There is a choice between two cylinders. Both diameters are 3.8"; both appear similar externally except the top/bottom of #2. One is solid. The other has a 0.5" inlet on top which leads to another cylindrical solid. The outlet has more cross sectional area than the inlet.

Will each perform identically or will the latter be more effective? ("Grab more" water)

Ascii art not the easiest on the phone, my thinking got me here mathematically:

Cylinder A X- sectional area = 1.9^2 * pi

Cylinder B's =

(1.9^2 * pi - 0.25^2 * pi) + (1^2 * pi)

i.e. 3.8" top with 0.5" inlet to 2" Cylinder beneath

Have no idea if B is correct... or leaning towards the correct idea. (2nd term effectively multiplied by coefficient < 1 but result > the cross sectional area of inlet)

Last edited: