- #1

Sem ten Wolde

- 1

- 0

Thread moved from the technical forums, so no HH Template is shown.

Dear users,

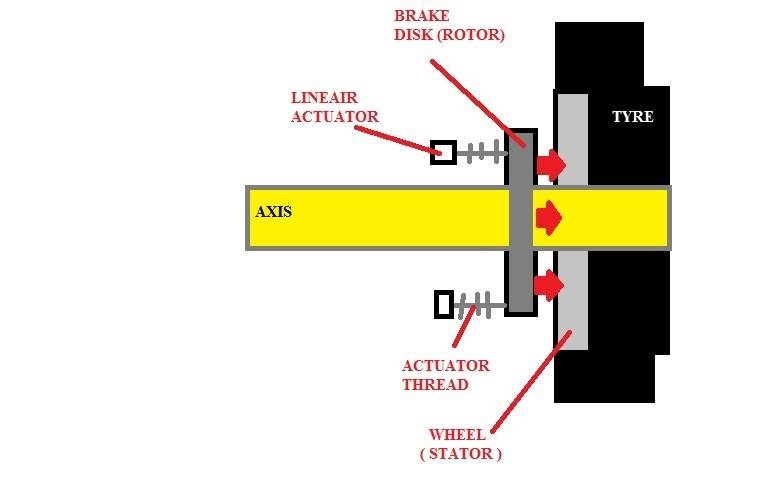

I have a problem with a calculation. I have got an assignment. For this assignment I have to redesign the brake actuators for the brake discs of the main landing gear of th fokker 100. I have forgotten how to calculate a force that goes sideways. The sideway forces are created when the lineair actuator pushes the brake disc on the wheels. For the calculation I have a few values.

- Total brake disc mass: 237,84 kg (90% worn brake, CS25.109i)

- CS-25 braking speed is= -3,0 m/s^2

- Assumed distance from neutral position actuator to the wheel= 5 cm

- Maximum take-off weight Fokker 100: 44.450 kg

- Kinetic energy brake discs: 162 MJ

- Maximum actuator force for each actuator: 40.000N

- Specific Heat of he brake disk material: 800 J/kg/K

- RTO test speed: 85m/s, 166 knots

- Effect of air resistance will be ignored, trust reverser and speedbrake on the wing will not be applied.

I have a few questions:

1 - Which formula do I need to determine the force that the actuators need to push the brake discs?

2 - How much actuators do I need in total on each wheel?

3 - What is the Work of each actuator?

4 - What is the Power of each actuator?

To be clear, I DON'T need to know the maximum kinetic energy capability of the brake disc, these questions are aimed only for the actuators. I need to know how much power the actuator need to produce and how much of them I need them on 1 wheel.

I have a problem with a calculation. I have got an assignment. For this assignment I have to redesign the brake actuators for the brake discs of the main landing gear of th fokker 100. I have forgotten how to calculate a force that goes sideways. The sideway forces are created when the lineair actuator pushes the brake disc on the wheels. For the calculation I have a few values.

- Total brake disc mass: 237,84 kg (90% worn brake, CS25.109i)

- CS-25 braking speed is= -3,0 m/s^2

- Assumed distance from neutral position actuator to the wheel= 5 cm

- Maximum take-off weight Fokker 100: 44.450 kg

- Kinetic energy brake discs: 162 MJ

- Maximum actuator force for each actuator: 40.000N

- Specific Heat of he brake disk material: 800 J/kg/K

- RTO test speed: 85m/s, 166 knots

- Effect of air resistance will be ignored, trust reverser and speedbrake on the wing will not be applied.

I have a few questions:

1 - Which formula do I need to determine the force that the actuators need to push the brake discs?

2 - How much actuators do I need in total on each wheel?

3 - What is the Work of each actuator?

4 - What is the Power of each actuator?

To be clear, I DON'T need to know the maximum kinetic energy capability of the brake disc, these questions are aimed only for the actuators. I need to know how much power the actuator need to produce and how much of them I need them on 1 wheel.