- #1

Hammad

- 22

- 1

hello,

How do i calculate brake size using force of actuation?

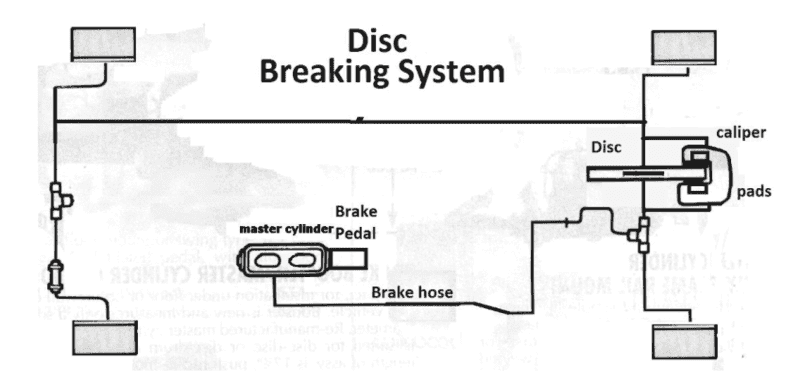

im designing a hydraulic disc braking system (only one rotor caliper located in the middle of drive shaft) for go kart and using simple pascal law, i have calculated the force of actuation of the hydraulic brake that is the force exerted by the piston on the brake pads. i have also calculated the maximum braking force and torque of the vehicle:

design of system:

now i want to calculate the brake size which should be able to stop the vehicle at 2.5 meter distance.

the kart specs are given below

-----------------------

The engine is 3.5 HP, 127 CC

total weight 170 Kg (loading condition)

stopping distance = 2.5 meters

Pedal ratio = 4:1

Pedal force = 300 N

The calculation i have done for maximum brake torque, force of actuation and brake torque using pedal ratio and pedal force is given below

assuming:

Area of piston = 0.00309677 m2

radius of rotor/disc = 0.07 m

distance from centre of piston to centre of wheel = 0.039

coefficient of friction onbetween pads and rotor = 0.61Force on master cylinder = 300 * 4 = 1200 N

Fbp= Fd * pedal ratio

Fd = input force on the brake pedal

Fbp= output force from brake pedal

Fbp=300 * 4 = 1200

Pmc= Fbp / Amc

Pmc = pressure exerted by master cylinder

Amc =effective piston area of the master sylinder

Pmc = 1200/0.000387096

Pmc = 31 x 10 4

Pcal = Pmc

Pcal = pressure exerted by caliper

Fcal = Pcal * Acal

Acal = area of the one side of the caliper

Fcal = 387500* (0.00309677)

Fcal = 9600N

T = 2 μ F r

T = 2 * 0.61 * 9600 * (0.07-0.031)

Breaking Torque = 456.77 N.m

xxxxxxxxxxxxxxxxxxxxx

maximum braking Force and torque at stopping distance of 2.5 m:

assuimg:

wheel radius = 0.125 m

coefficient of friction btw tyre and road = 0.5

0 = u 2 + 2as

u = 50 km/hr

s = stopping distance = 2.5 meters

a = deceleration = 38.58 m/s2

F= ma =170 x 38.58= 6.5 KN

T = 2uFr

u = coefficient of friction = 0.61

r = radius of wheel = 0.25/2 m = 0.125 m

T = 2*0.5*6500*0.125

T = 812.5 N.m

How do i now calculate the size of the brakes?

How do i calculate brake size using force of actuation?

im designing a hydraulic disc braking system (only one rotor caliper located in the middle of drive shaft) for go kart and using simple pascal law, i have calculated the force of actuation of the hydraulic brake that is the force exerted by the piston on the brake pads. i have also calculated the maximum braking force and torque of the vehicle:

design of system:

now i want to calculate the brake size which should be able to stop the vehicle at 2.5 meter distance.

the kart specs are given below

-----------------------

The engine is 3.5 HP, 127 CC

total weight 170 Kg (loading condition)

stopping distance = 2.5 meters

Pedal ratio = 4:1

Pedal force = 300 N

The calculation i have done for maximum brake torque, force of actuation and brake torque using pedal ratio and pedal force is given below

assuming:

Area of piston = 0.00309677 m2

radius of rotor/disc = 0.07 m

distance from centre of piston to centre of wheel = 0.039

coefficient of friction onbetween pads and rotor = 0.61Force on master cylinder = 300 * 4 = 1200 N

Fbp= Fd * pedal ratio

Fd = input force on the brake pedal

Fbp= output force from brake pedal

Fbp=300 * 4 = 1200

Pmc= Fbp / Amc

Pmc = pressure exerted by master cylinder

Amc =effective piston area of the master sylinder

Pmc = 1200/0.000387096

Pmc = 31 x 10 4

Pcal = Pmc

Pcal = pressure exerted by caliper

Fcal = Pcal * Acal

Acal = area of the one side of the caliper

Fcal = 387500* (0.00309677)

Fcal = 9600N

T = 2 μ F r

T = 2 * 0.61 * 9600 * (0.07-0.031)

Breaking Torque = 456.77 N.m

xxxxxxxxxxxxxxxxxxxxx

maximum braking Force and torque at stopping distance of 2.5 m:

assuimg:

wheel radius = 0.125 m

coefficient of friction btw tyre and road = 0.5

0 = u 2 + 2as

u = 50 km/hr

s = stopping distance = 2.5 meters

a = deceleration = 38.58 m/s2

F= ma =170 x 38.58= 6.5 KN

T = 2uFr

u = coefficient of friction = 0.61

r = radius of wheel = 0.25/2 m = 0.125 m

T = 2*0.5*6500*0.125

T = 812.5 N.m

How do i now calculate the size of the brakes?

Attachments

Last edited: