- #1

Doc

- 47

- 4

Hi all,

My university did not provide any metrology courses as part of my degree, and our lab experiment sessions are not very hands on, unfortunately. Thus, I am a bit out of my depth. I need to calibrate some temperature sensors as part of my mechanical engineering internship.

I have an 8 channel data acquisition unit with 8 assorted sensors attached: SMDs, RTDs, and general purpose probes. I submerged these sensors into a bath of ice water, and later a bath of boiling water in order to set baselines for zero degrees and one hundred degrees Celsius. I will be redoing the ice water bath and the boiling water bath as I am not satisfied that I did these properly the first time around. I have confirmed that all sensors are working by monitoring their real-time temperature readings as I held them between my fingers.

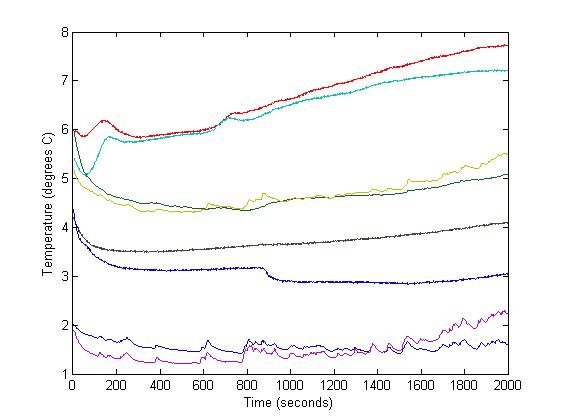

Shown below in Figure 1 is the data output for the ice water submersion. I will ignore the boiling water for the time being.

Figure 1: Logged temperature data from ice water bath.

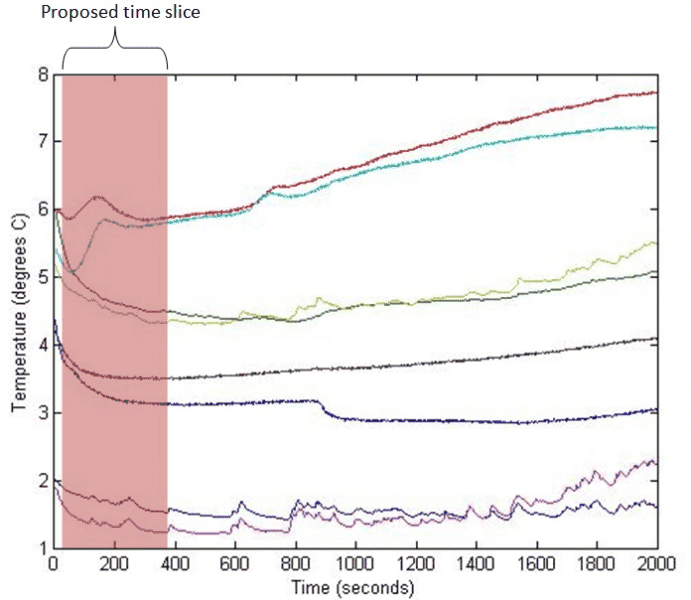

This is what I think I need to do next: select a time slice near the beginning of the submersion so that I know that the water is still as close to zero degrees as possible (the time slice that I am proposing to use is shown below in Figure 2), and find the mean value of each of the temperature sensors for the example time slice.

Figure 2: Proposed time slice for determining mean values for each sensor. I feel that this time slice is too larger, however. A slice from the 200 second mark to the 300 second mark may be more appropriate?

The mean value will then be an offset that I will need to subtract from my measured data (my measured data being logged temperature measurements after the calibration has been completed). For example: if I measure 20 degrees Celsius on sensor 3 (and the mean value during calibration for the ice water was 3 degrees Celsius) then I would need to do 20 – 3 Celsius to determine the actual temperature is 17 degrees Celsius.

I am pretty uncertain of most of the things that I have proposed above, so I would greatly appreciate any input.

Doc

My university did not provide any metrology courses as part of my degree, and our lab experiment sessions are not very hands on, unfortunately. Thus, I am a bit out of my depth. I need to calibrate some temperature sensors as part of my mechanical engineering internship.

I have an 8 channel data acquisition unit with 8 assorted sensors attached: SMDs, RTDs, and general purpose probes. I submerged these sensors into a bath of ice water, and later a bath of boiling water in order to set baselines for zero degrees and one hundred degrees Celsius. I will be redoing the ice water bath and the boiling water bath as I am not satisfied that I did these properly the first time around. I have confirmed that all sensors are working by monitoring their real-time temperature readings as I held them between my fingers.

Shown below in Figure 1 is the data output for the ice water submersion. I will ignore the boiling water for the time being.

Figure 1: Logged temperature data from ice water bath.

This is what I think I need to do next: select a time slice near the beginning of the submersion so that I know that the water is still as close to zero degrees as possible (the time slice that I am proposing to use is shown below in Figure 2), and find the mean value of each of the temperature sensors for the example time slice.

Figure 2: Proposed time slice for determining mean values for each sensor. I feel that this time slice is too larger, however. A slice from the 200 second mark to the 300 second mark may be more appropriate?

The mean value will then be an offset that I will need to subtract from my measured data (my measured data being logged temperature measurements after the calibration has been completed). For example: if I measure 20 degrees Celsius on sensor 3 (and the mean value during calibration for the ice water was 3 degrees Celsius) then I would need to do 20 – 3 Celsius to determine the actual temperature is 17 degrees Celsius.

I am pretty uncertain of most of the things that I have proposed above, so I would greatly appreciate any input.

Doc