- #1

Amaelle

- 310

- 54

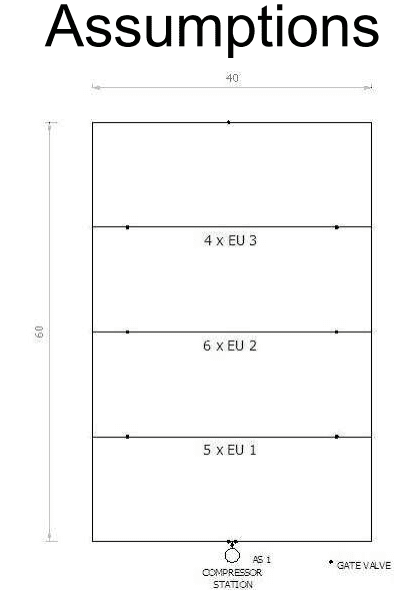

Good day I'm trying to calculate the pressure drop in each branch of the following loop ring system

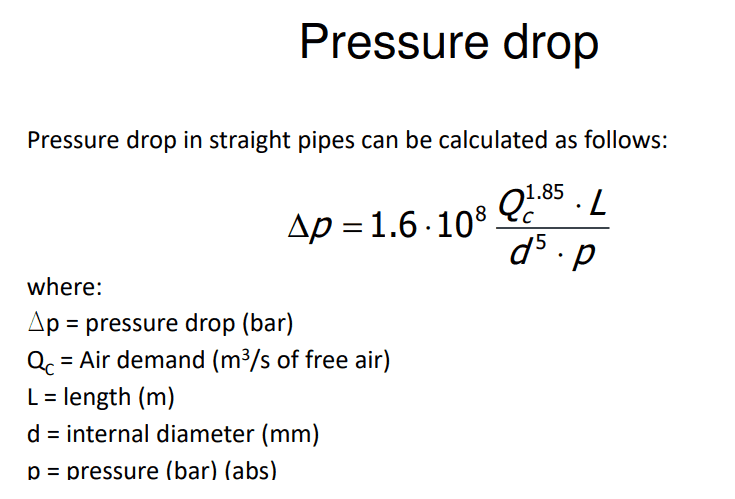

I used the following formula to find the pressure drop

but i seems that it worked only for the ring, and the branch #2 ( the branch in the middle), the solution given by the professor show different results for the other branch!( in each branch there is one valve and one reducer)

any help would be highly appreciated!

best regards

I used the following formula to find the pressure drop

but i seems that it worked only for the ring, and the branch #2 ( the branch in the middle), the solution given by the professor show different results for the other branch!( in each branch there is one valve and one reducer)

any help would be highly appreciated!

best regards