- #1

Tim in NY

- 6

- 0

I have an electromagnet device that I am designing and need a bit of help from some of the brilliant people on this site. Here's the problem:

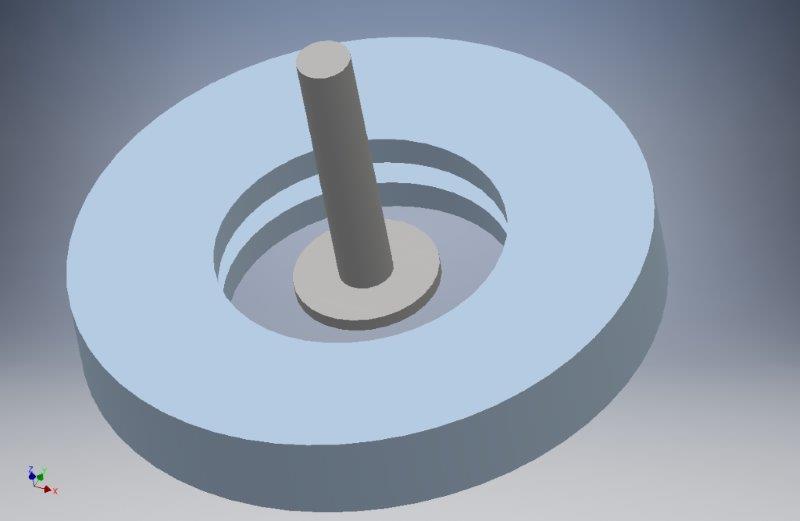

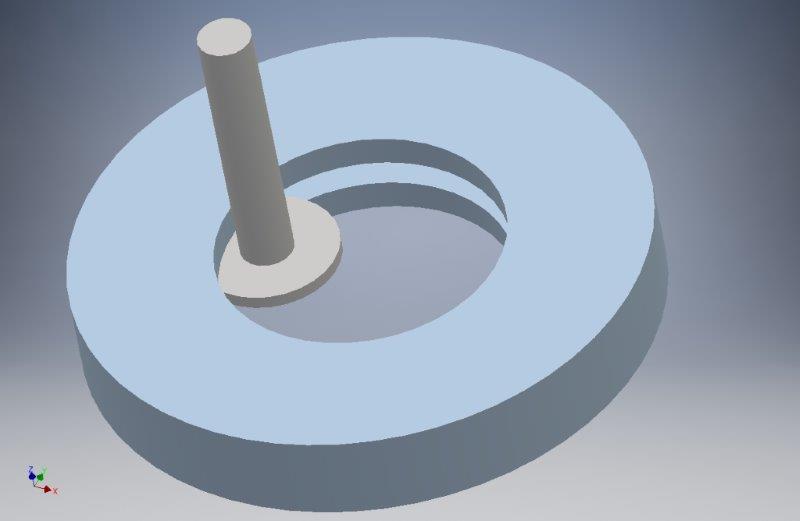

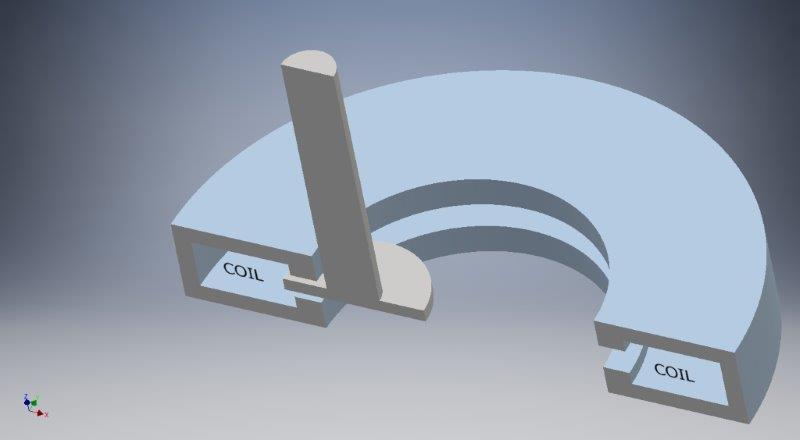

I have a disk attached to the end of a shaft and the shaft/disk assembly can move radially (via a spring loaded mechanism). This shaft/disk fits within the inside diameter of a donut shaped electromagnet consisting of a coil surrounded by an iron armature. The electromagnet is stationary.

When the shaft moves radially over to the side of the ID of the magnet, the magnet is then energized to temporarily to hold the shaft/disk against the ID (the magnet does not cause the movement). After a set amount of time the magnet is de-energized releasing the shaft/disk which returns back to center. The radial movement can happen in any direction (0 to 360°) and

Here's a sectional image:

Here's very preliminary data just to get an idea of sizes: Magnet Iron Armature OD = 10" ID=5". Disk OD= 4", Shaft=1.5", and a force of around approx 8 lbs.

So here are my questions:

1) I've been looking but have not been able to find any physics papers on this type of magnet. I'm trying to find formulas and some theory for optimum dimensions, coil sizes, wire sizes etc. (it's been 40 years since I had this type of physics in college...ugh) Any links that you can provide would be great!

2) What is the best orientation of the coil's winding to create a radial force?

Any help would be appreciated! ...and thank you in advance!

Tim

I have a disk attached to the end of a shaft and the shaft/disk assembly can move radially (via a spring loaded mechanism). This shaft/disk fits within the inside diameter of a donut shaped electromagnet consisting of a coil surrounded by an iron armature. The electromagnet is stationary.

When the shaft moves radially over to the side of the ID of the magnet, the magnet is then energized to temporarily to hold the shaft/disk against the ID (the magnet does not cause the movement). After a set amount of time the magnet is de-energized releasing the shaft/disk which returns back to center. The radial movement can happen in any direction (0 to 360°) and

Here's a sectional image:

Here's very preliminary data just to get an idea of sizes: Magnet Iron Armature OD = 10" ID=5". Disk OD= 4", Shaft=1.5", and a force of around approx 8 lbs.

So here are my questions:

1) I've been looking but have not been able to find any physics papers on this type of magnet. I'm trying to find formulas and some theory for optimum dimensions, coil sizes, wire sizes etc. (it's been 40 years since I had this type of physics in college...ugh) Any links that you can provide would be great!

2) What is the best orientation of the coil's winding to create a radial force?

Any help would be appreciated! ...and thank you in advance!

Tim

Attachments

Last edited: