- #1

Sprotz

- 7

- 0

So far I have not found a satisfactory answer anywhere on the internet for this one. I have read the "race car suspension class" section but could not find the bit I am interested in. I am trying to simulate vehicle spin out / oversteer by reducing traction on the rear wheels when cornering. My physics engine does not automatically calculate wheel load when cornering so I have to do it myself. I know two separate equations that calculate load on the wheels. One for longitudnal deceleration when braking, and one for lateral deceleration when cornering.

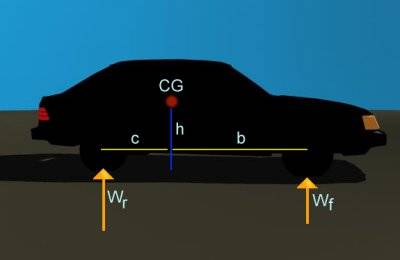

For a stationary vehicle, the wheel load on each axle is calculated as:

Wf=(c/L)*W for the front axle

Wr=(b/L)*W for the rear axle

where c is the distance between the center of gravity and the rear axle, b is the distance between the center of gravity and the front axle, L is the wheelbase and W is the weight of the vehicle.

So during deceleration, the weight transfer on each axle is given by

Wf=(c/L)*W - (h/L)*M*a for the front axle

Wr=(b/L)*W + (h/L)*M*a for the rear axle

where h is the height of the center of gravity, M is the mass of the vehicle and a is acceleration/deceleration.

So the weight on each tyre for a stationary car would be Wf/2 for each front tyre and Wr/2 for each rear tyre, since the weight is distributed equally to these tyres if the center of gravity is at the half way point of the track width.

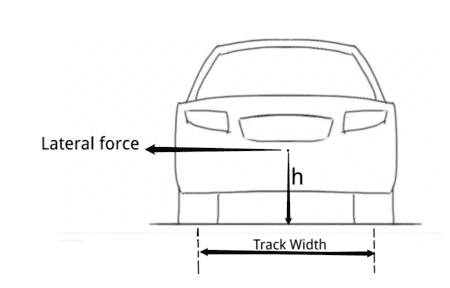

And the separate equation for weight transfer to the wheels during cornering, this is the equation for weight transfer for lateral deceleration is given by:

Weight transfer=(Lateral deceleration/g)*W*h/Track width

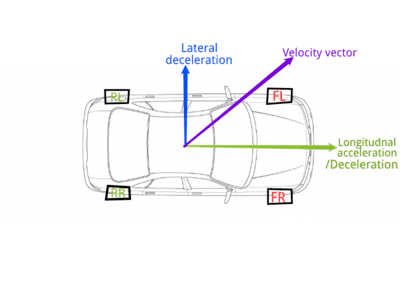

Now how do I combine the two equations to give an equation that gives the weight transfer on each of the four wheels during both braking and cornering? So that I get the weight on each wheel instead of just on each axle?

Say, the car is both cornering and decelerating, and I simply got the longitudnal weight transfer divided by 2 on the front left tyre (FL) and added it to the lateral weight transfer divided by 2, would it be correct?

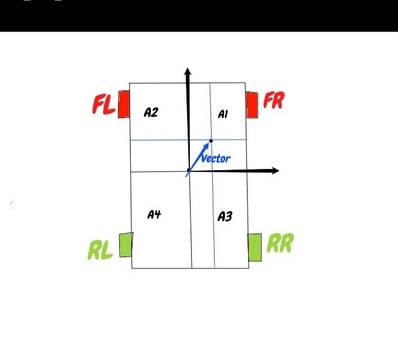

Or if I shifted the weight along the velocity vector by distance depending on deceleration and got the load distribution on each tyre as inversely proportional to the area of rectangle encompassing the wheel as shown below, where load on the front right tyre is inversely proportional to area A1. Same for the other tyres.

The above assumes that there is no suspension for simplicity. So is any of the above solutions correct or is there another way of determining the load on each wheel? I need the simplest possible solution that is just enough to simulate spin out and I don't need a too realistic model, and please I prefer you answer if you know the solution, or a link to it as in my previous posts some people gave comments without really answering, or gave answers like "it's complicated" or "how can you calculate this without calculating that".

Or if you know Unity's vehicle physics engine, explain how to add spin out.

For a stationary vehicle, the wheel load on each axle is calculated as:

Wf=(c/L)*W for the front axle

Wr=(b/L)*W for the rear axle

where c is the distance between the center of gravity and the rear axle, b is the distance between the center of gravity and the front axle, L is the wheelbase and W is the weight of the vehicle.

So during deceleration, the weight transfer on each axle is given by

Wf=(c/L)*W - (h/L)*M*a for the front axle

Wr=(b/L)*W + (h/L)*M*a for the rear axle

where h is the height of the center of gravity, M is the mass of the vehicle and a is acceleration/deceleration.

So the weight on each tyre for a stationary car would be Wf/2 for each front tyre and Wr/2 for each rear tyre, since the weight is distributed equally to these tyres if the center of gravity is at the half way point of the track width.

And the separate equation for weight transfer to the wheels during cornering, this is the equation for weight transfer for lateral deceleration is given by:

Weight transfer=(Lateral deceleration/g)*W*h/Track width

Now how do I combine the two equations to give an equation that gives the weight transfer on each of the four wheels during both braking and cornering? So that I get the weight on each wheel instead of just on each axle?

Say, the car is both cornering and decelerating, and I simply got the longitudnal weight transfer divided by 2 on the front left tyre (FL) and added it to the lateral weight transfer divided by 2, would it be correct?

Or if I shifted the weight along the velocity vector by distance depending on deceleration and got the load distribution on each tyre as inversely proportional to the area of rectangle encompassing the wheel as shown below, where load on the front right tyre is inversely proportional to area A1. Same for the other tyres.

The above assumes that there is no suspension for simplicity. So is any of the above solutions correct or is there another way of determining the load on each wheel? I need the simplest possible solution that is just enough to simulate spin out and I don't need a too realistic model, and please I prefer you answer if you know the solution, or a link to it as in my previous posts some people gave comments without really answering, or gave answers like "it's complicated" or "how can you calculate this without calculating that".

Or if you know Unity's vehicle physics engine, explain how to add spin out.

Attachments

Last edited: