- #1

Mary09

- 7

- 0

Hey everyone,

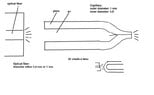

I am trying to couple light from an optical fiber connected to an LED (365nm) into a small glass capillary which is pulled on one end and should be used as a small light source. The idea is to use the glass as a light guide. Has anyone tips for efficient incoupling of the light?

I would really appreciate your help.

I am trying to couple light from an optical fiber connected to an LED (365nm) into a small glass capillary which is pulled on one end and should be used as a small light source. The idea is to use the glass as a light guide. Has anyone tips for efficient incoupling of the light?

I would really appreciate your help.