- #1

Dare Diamond

- 5

- 0

Hello everyone.

I am glad I came across this science oriented Forum site.

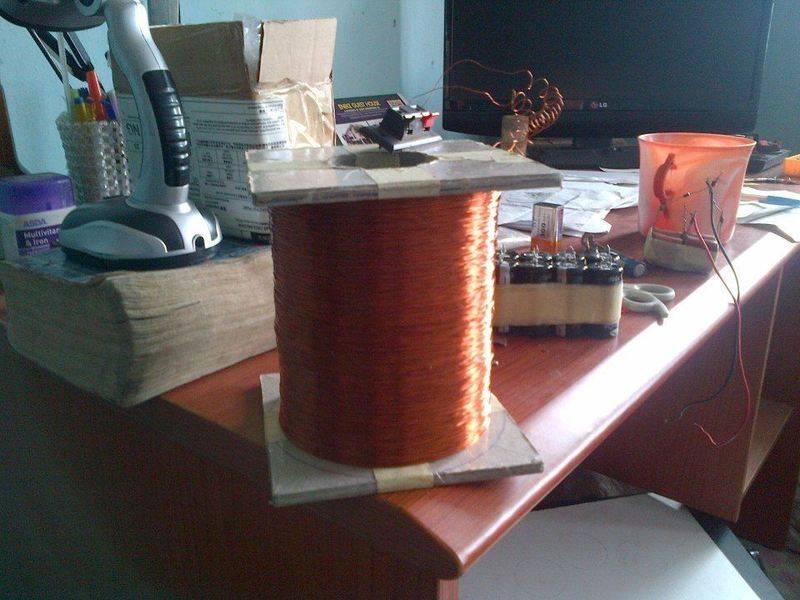

I actually get there from Google and what I am deeply curious to know about is the amount of Maximum Voltage my 3.5kg Air Core Electromagnet can bear.

The Core of the Solenoid is 120mm in height and 13inches in Diameter.

It core is 47mm wide and 130mm long.

I used 0.31mm thick enameled copper wire to make it and after winding it reads 1.14KOhms.

Please may I know the maximum Voltage to apply to it in other not to get it burnt?

How do I calculate that?

I am glad I came across this science oriented Forum site.

I actually get there from Google and what I am deeply curious to know about is the amount of Maximum Voltage my 3.5kg Air Core Electromagnet can bear.

The Core of the Solenoid is 120mm in height and 13inches in Diameter.

It core is 47mm wide and 130mm long.

I used 0.31mm thick enameled copper wire to make it and after winding it reads 1.14KOhms.

Please may I know the maximum Voltage to apply to it in other not to get it burnt?

How do I calculate that?