- #1

Joe85

- 29

- 3

Hi all, the question has been posed many times, unfortunetly, there does not seem to be any explanation for finding the mode of buckling in Question 3B part ii, hence we i am posting.

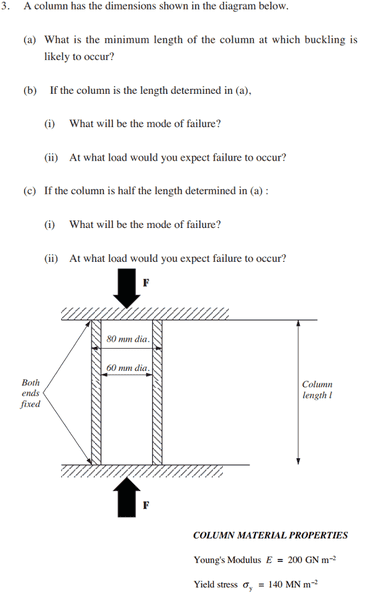

1. Homework Statement

Below in image

Also elow in image

The lesson mentions that:

The minimum E.S.R. for which buckling occurs, is the one when the critical stress σc equal to the yield stress of the material σy. For a mild steel with E=200GPa and σc=σy=240MPa, the slenderness ratio is about 91. That means when effective slenderness ratios are less than 91 crushing is the failure mode, for values above 91 buckling is the mode.

I hvae taken this to mean:

E.S.R = 118.74

Slenderness Ration = L/K = 5.94/25*10^-3 = 237.6

Since the Slenderness Ratio of the column is 237.6 and the ESR is <237.6 the column is short and the mode of failure would be Crushing.

Am i barking up the wrong tree with this?

I have

A = 2199.11*10-6M2

K= 25x10-3M

I=1374446.9*10-12M4

E=200*109Nm-2

Oy=140*106Nm-2

E.S.R = √π2(200*109)/140*106 = 118.74

OR

Is it really as simple as saying that it could be either, since the minimum length that buckling can occur is 5.94m, which just so happens to be the length of our column.

Similarly for Part C, since we have now halved the length of the column, we are well below the minimum length for buckling, so it must be crushing?Thanks in advance.

Joe.

1. Homework Statement

Below in image

Homework Equations

Also elow in image

The Attempt at a Solution

The lesson mentions that:

The minimum E.S.R. for which buckling occurs, is the one when the critical stress σc equal to the yield stress of the material σy. For a mild steel with E=200GPa and σc=σy=240MPa, the slenderness ratio is about 91. That means when effective slenderness ratios are less than 91 crushing is the failure mode, for values above 91 buckling is the mode.

I hvae taken this to mean:

E.S.R = 118.74

Slenderness Ration = L/K = 5.94/25*10^-3 = 237.6

Since the Slenderness Ratio of the column is 237.6 and the ESR is <237.6 the column is short and the mode of failure would be Crushing.

Am i barking up the wrong tree with this?

I have

A = 2199.11*10-6M2

K= 25x10-3M

I=1374446.9*10-12M4

E=200*109Nm-2

Oy=140*106Nm-2

E.S.R = √π2(200*109)/140*106 = 118.74

OR

Is it really as simple as saying that it could be either, since the minimum length that buckling can occur is 5.94m, which just so happens to be the length of our column.

Similarly for Part C, since we have now halved the length of the column, we are well below the minimum length for buckling, so it must be crushing?Thanks in advance.

Joe.

Attachments

Last edited: