- #1

abdulbadii

- 43

- 1

- TL;DR Summary

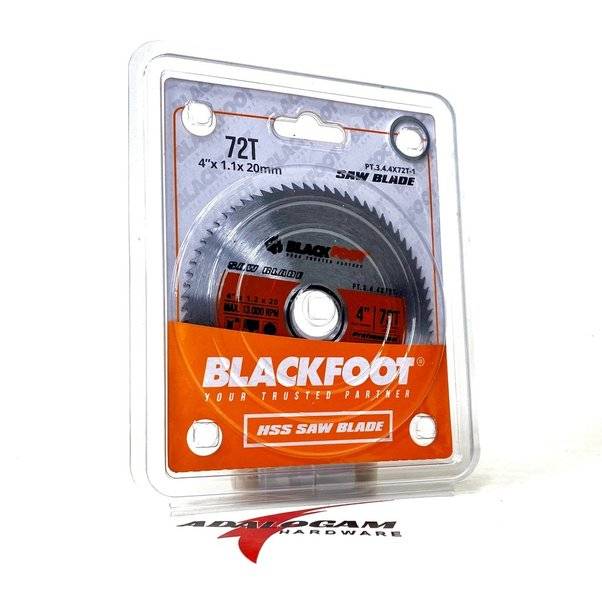

- How to read and understand a wood cutting blade specification

How do we read and understand a wood cutting blade specification (e.g. below) ?

Is the grinder spacer flange nut for 16 mm center diameter metal cutting disc can safely be used for 20 mm one of such blade?

Is the grinder spacer flange nut for 16 mm center diameter metal cutting disc can safely be used for 20 mm one of such blade?