- #1

Mormont

- 9

- 0

Hello All,

Very new to design , especially in material selection and rubber stuff.

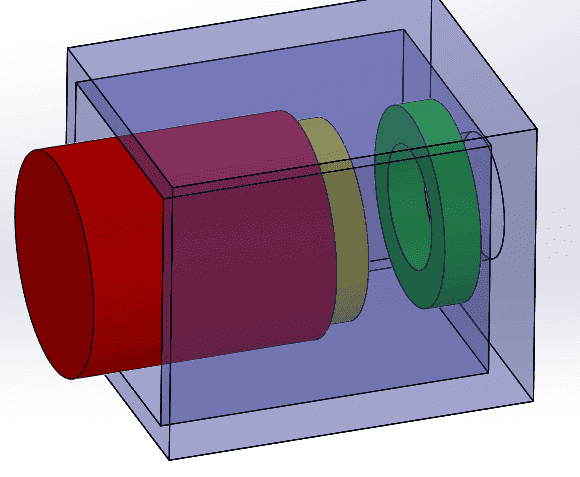

I have requirement where piston/shaft reciprocates to housing at high speeds. In order to reduce noise and for safety reasons, I must add rubber pads on both. Application as below:

Red part is the shaft/piston (around 15mm Dia.) with a yellow rubber pad

Blue part is the housing with green rubber pad.

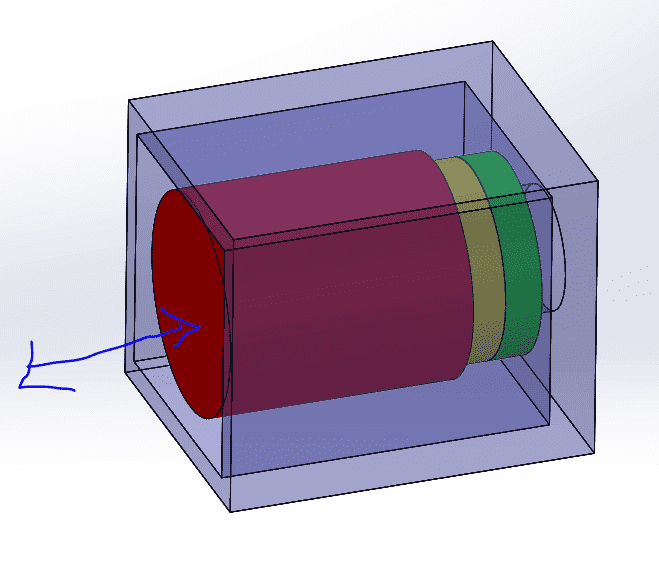

Arrow indicated in 2nd pic for direction of reciprocation.

Speed is around 25-30 Hz for reciprocating movement.

Queries;

1. What rubber material I could use for such application?

2. Is there any food grade rubber for this application?

3. What could be major design consideration for this?

Any direction or resources would help.

Thanks!

Very new to design , especially in material selection and rubber stuff.

I have requirement where piston/shaft reciprocates to housing at high speeds. In order to reduce noise and for safety reasons, I must add rubber pads on both. Application as below:

Red part is the shaft/piston (around 15mm Dia.) with a yellow rubber pad

Blue part is the housing with green rubber pad.

Arrow indicated in 2nd pic for direction of reciprocation.

Speed is around 25-30 Hz for reciprocating movement.

Queries;

1. What rubber material I could use for such application?

2. Is there any food grade rubber for this application?

3. What could be major design consideration for this?

Any direction or resources would help.

Thanks!