- #1

amrmohammed

- 45

- 0

Hello,

Why do self regulating heating cables have such low power output per foot?

Power output in these cables does not exceed 20 W/ft at 10 degree C, and decreases as the temperature goes up.

Many of the cables I saw can withstand high temperatures (250 degree C power off and 150 degree C power on), so why can't we supply more current to get more heat density?

The manufacturers of such cables provide the maximum current to be supplied as a value per foot, so that the longer the cable the more current you can apply through it. Which I don't understand, what happens if I applied more than the max rated current in short cable, and made sure that heat transfer coefficient is high enough.

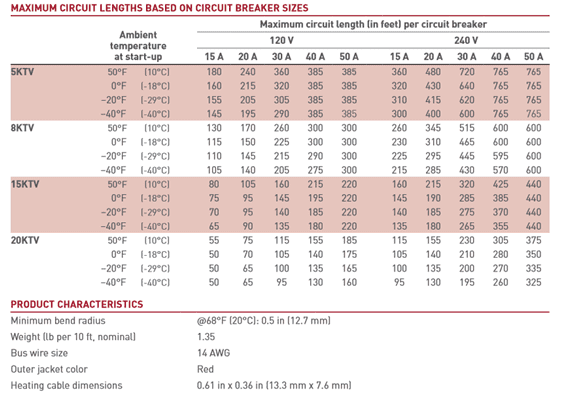

One of the cables datasheet here.

Why do self regulating heating cables have such low power output per foot?

Power output in these cables does not exceed 20 W/ft at 10 degree C, and decreases as the temperature goes up.

Many of the cables I saw can withstand high temperatures (250 degree C power off and 150 degree C power on), so why can't we supply more current to get more heat density?

The manufacturers of such cables provide the maximum current to be supplied as a value per foot, so that the longer the cable the more current you can apply through it. Which I don't understand, what happens if I applied more than the max rated current in short cable, and made sure that heat transfer coefficient is high enough.

One of the cables datasheet here.