- #1

Drew Sandlin

- 5

- 0

- TL;DR Summary

- How do you analyze the stresses on the bail on a lifting plate?

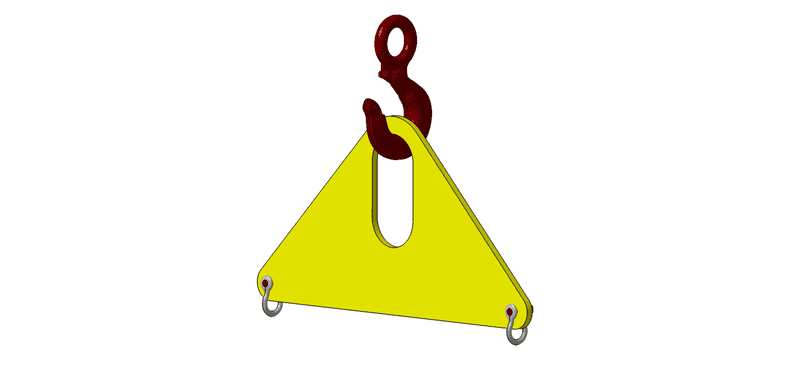

I'm designing a custom lifting plate that has two shackles hanging from it and a large slot at the top for hooking into an overhead crane. I have a few stress analysis questions:

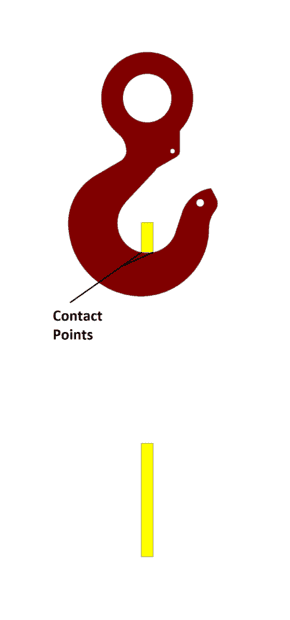

1. The plate will be cut on a waterjet table, which means the slot will have sharp edges, and that the hook will contact the inside of the slot on the lifting plate at two points. See the attached pictures. What is the best way to analyze these contact stresses? Case 4 in Table 14.1 in Roark's Formulas for Stress and Strain, page 704? Is this something I should even be concerned about?

2. The bail at the top of the lift plate is approximately a curved beam. Can I analyze an equivalent curved beam that fits within the plate profile, and assume the stresses in the actual plate will be no higher than the stresses in this hypothetical curved beam?

3. For the bending strength of the plate, can I take a similar approach to (2) and analyze a smaller rectangular beam that fits within the plate profile and assume the stresses in the actual plate will be no higher the stresses in this hypothetical beam?

4. I've been reading through ASME BTH-1 and my understanding is it gives safety factors for certain loading scenarios and member designs, but leaves the method of determining stresses up to the analyst. Is that an accurate statement?

5. Does laser cutting this plate versus waterjetting it affect fatigue life for the plate? I couldn't find anything in ASME BTH-1 that discusses this. I could have missed it. Are there any considerations that need to be accounted for in the heat affected zone if components in a lifting device were laser cut?

Maybe what I'm really asking for is, "how would you approach analyzing this lifting plate to show it's compliant with ASME BTH-1?"

1. The plate will be cut on a waterjet table, which means the slot will have sharp edges, and that the hook will contact the inside of the slot on the lifting plate at two points. See the attached pictures. What is the best way to analyze these contact stresses? Case 4 in Table 14.1 in Roark's Formulas for Stress and Strain, page 704? Is this something I should even be concerned about?

2. The bail at the top of the lift plate is approximately a curved beam. Can I analyze an equivalent curved beam that fits within the plate profile, and assume the stresses in the actual plate will be no higher than the stresses in this hypothetical curved beam?

3. For the bending strength of the plate, can I take a similar approach to (2) and analyze a smaller rectangular beam that fits within the plate profile and assume the stresses in the actual plate will be no higher the stresses in this hypothetical beam?

4. I've been reading through ASME BTH-1 and my understanding is it gives safety factors for certain loading scenarios and member designs, but leaves the method of determining stresses up to the analyst. Is that an accurate statement?

5. Does laser cutting this plate versus waterjetting it affect fatigue life for the plate? I couldn't find anything in ASME BTH-1 that discusses this. I could have missed it. Are there any considerations that need to be accounted for in the heat affected zone if components in a lifting device were laser cut?

Maybe what I'm really asking for is, "how would you approach analyzing this lifting plate to show it's compliant with ASME BTH-1?"

Last edited by a moderator: