- #1

Saladsamurai

- 3,020

- 7

Hello All,

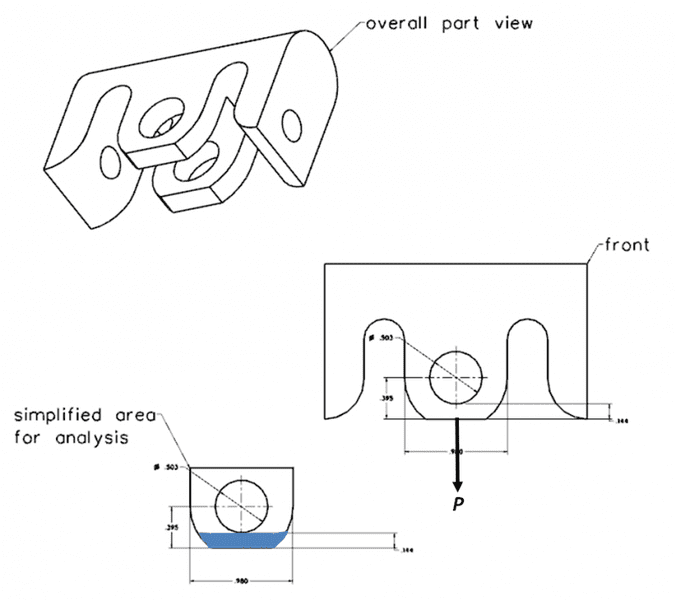

I have a fixture that is used for lifting an engine. See attached image for the part in question. You can see in the 'front' view the hole where a pin passes through the part and the lifting lug of the engine. You can also see the loading.

We want to machine the part down such that the .144 dimension goes down to .070. I am just wondering what king of analysis I can do on this? I have a view with the assumed simplified area for analysis. Here is what I am thinking of doing:

1. Shear stress on front face. Do I use only the blue-shaded area? Or do I use the full area with some sort of consideration for the hole? If the latter, do you know where I can learn about such a model?

2. The pin makes contact with the hole along its thickness so I would need to look at the normal stress on the inside of the hole. The surface is cylindrical so I am wondering if there is a common practice for this? If so, where can I see it?

I am going through "Roark's Formulas for Stress and Strain" and "Shigley's" to see what I can come up with, but if someone with some experience could chime in, that would be great. I don't have a lot of support at my company (yet, we're hiring some experience now).

Thank you for your time.

I have a fixture that is used for lifting an engine. See attached image for the part in question. You can see in the 'front' view the hole where a pin passes through the part and the lifting lug of the engine. You can also see the loading.

We want to machine the part down such that the .144 dimension goes down to .070. I am just wondering what king of analysis I can do on this? I have a view with the assumed simplified area for analysis. Here is what I am thinking of doing:

1. Shear stress on front face. Do I use only the blue-shaded area? Or do I use the full area with some sort of consideration for the hole? If the latter, do you know where I can learn about such a model?

2. The pin makes contact with the hole along its thickness so I would need to look at the normal stress on the inside of the hole. The surface is cylindrical so I am wondering if there is a common practice for this? If so, where can I see it?

I am going through "Roark's Formulas for Stress and Strain" and "Shigley's" to see what I can come up with, but if someone with some experience could chime in, that would be great. I don't have a lot of support at my company (yet, we're hiring some experience now).

Thank you for your time.