- #1

oemmake

- 7

- 0

Hello everyone,

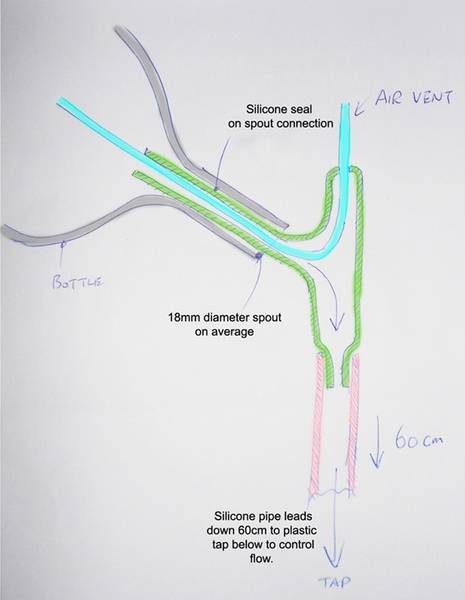

I really feel out of my depth here, especially with this simple question. I'm trying to rig something up and understand why it's not working. With a pipe connected to a wine bottle sized bottle, syrup won't flow into the pipe (1cm diameter, 60cm long, down to a tap). For normal liquids like wine or water, this system seems to work ok:

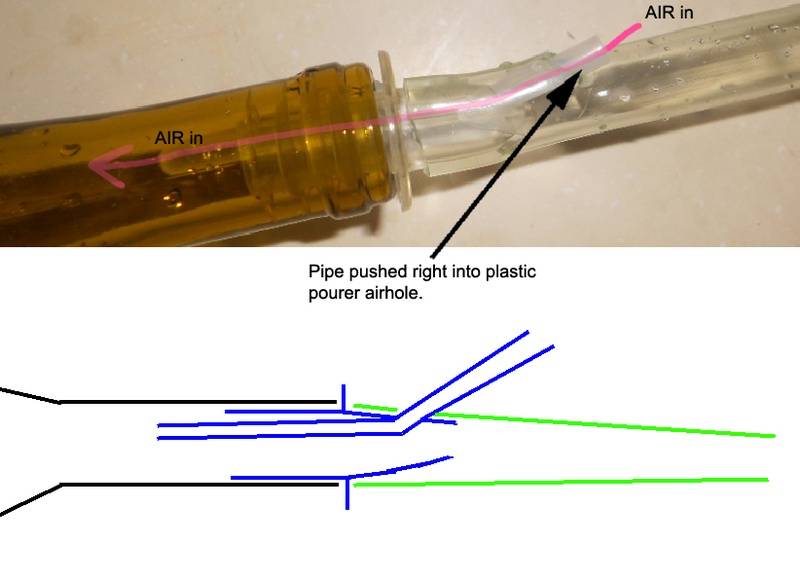

However, with thicker liquids (i.e. sugar syrup, (consistency similar to full fat milk, its not flowing). I'm hoping for pointers on how to make the syrup flow down the pipe once the tap at the bottom is opened at the bottom. Right now it's not flowing at all. I've been tinkering with pipes and connections, such as the image below:

What would I need to do to the first drawing, to make thicker liquids flow easier?

many thanks / simon

I really feel out of my depth here, especially with this simple question. I'm trying to rig something up and understand why it's not working. With a pipe connected to a wine bottle sized bottle, syrup won't flow into the pipe (1cm diameter, 60cm long, down to a tap). For normal liquids like wine or water, this system seems to work ok:

However, with thicker liquids (i.e. sugar syrup, (consistency similar to full fat milk, its not flowing). I'm hoping for pointers on how to make the syrup flow down the pipe once the tap at the bottom is opened at the bottom. Right now it's not flowing at all. I've been tinkering with pipes and connections, such as the image below:

What would I need to do to the first drawing, to make thicker liquids flow easier?

many thanks / simon