- #1

Yevhenii

- 7

- 0

- TL;DR Summary

- Torque calculation

I'm designing loading mechanism of new machine and need to know what the torque will be.

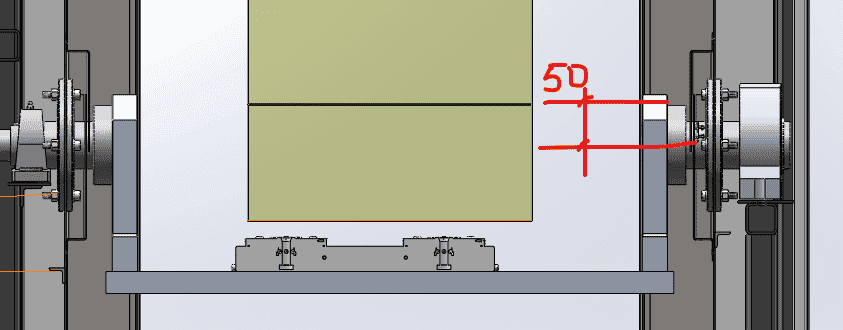

Here is the sketch of my mechanism.

Distance from centre of shaft to the top of loading table is 200mm. Distance from the centre of mass of workpiece to centre of the shaft 50 mm. Max load is 400 kg. Weight of loading table is 50 kg.

Do I need (at first) calculate moment of inertia and then angular speed, and after I will know what torque i need? Or I just need to multiply force on distance?

This mechanism should rotate to 180 deg. n=14 rpm

Thanks

Here is the sketch of my mechanism.

Distance from centre of shaft to the top of loading table is 200mm. Distance from the centre of mass of workpiece to centre of the shaft 50 mm. Max load is 400 kg. Weight of loading table is 50 kg.

Do I need (at first) calculate moment of inertia and then angular speed, and after I will know what torque i need? Or I just need to multiply force on distance?

This mechanism should rotate to 180 deg. n=14 rpm

Thanks