- #1

zabala9

- 11

- 0

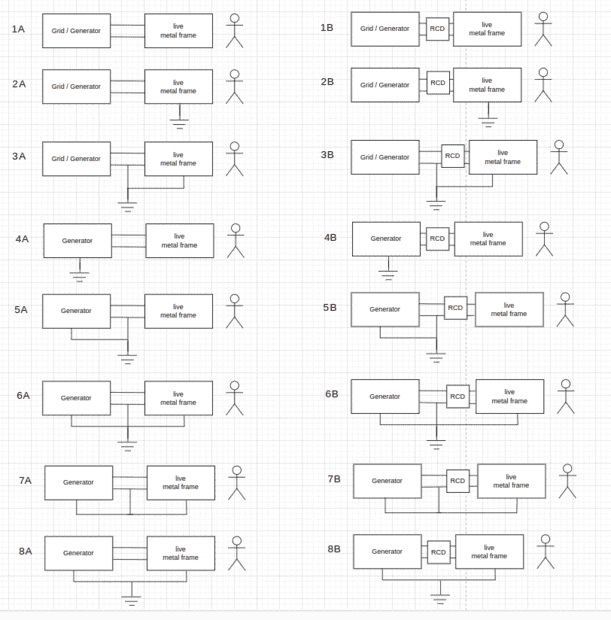

Hello, let's say the AC generator and the washing machine, with a live metal frame due to a fault, are floating-neutral and floating-ground. These are many combinations where both get and get not bonded/grounded. Can anybody tell us in which case the person gets an electric shock when touches the metal frame, and why? The person is standing on the soil with bare feet, and with shoes (to put both cases)

This isn't a homework, it is just that there are a lot of different opinions on the internet and some confusion in me and many people. I added with/without RCD/GFCI breaker cases to make this more complete

thanks

This isn't a homework, it is just that there are a lot of different opinions on the internet and some confusion in me and many people. I added with/without RCD/GFCI breaker cases to make this more complete

thanks

Last edited by a moderator: