- #1

- 3,645

- 1,528

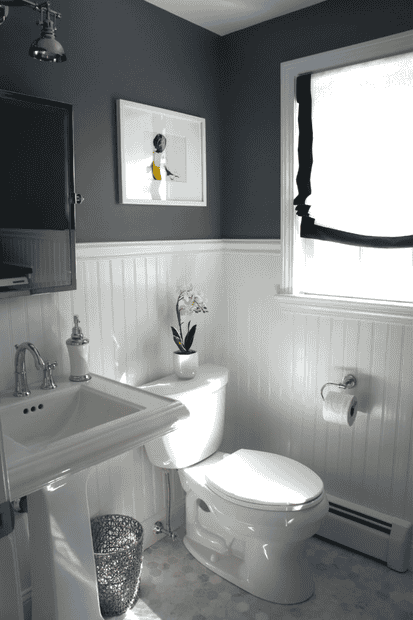

I'm remodeling a bathroom (my own). One of the upgrades is Wainscot thin decorative paneling that goes partially up a wall.

Question 1: surely you don't need to miter the corner joints of the panels @ 45° since they are only a 1/4 thick?

Question 2: Is it better to put the paneling against the wall, nail the molding to it and drywall, or put it between moldings, nailed to the drywall; nailing the molding above and below the paneling independently. I'm wondering if the straightness of the cut being done free hand with circular saw will be an issue in the second method, and with the first method the vertical grooves in the paneling will be behind the molding...seeming to make a place for moisture to collect.

Just looking for some tips...before I start nailing!

Question 1: surely you don't need to miter the corner joints of the panels @ 45° since they are only a 1/4 thick?

Question 2: Is it better to put the paneling against the wall, nail the molding to it and drywall, or put it between moldings, nailed to the drywall; nailing the molding above and below the paneling independently. I'm wondering if the straightness of the cut being done free hand with circular saw will be an issue in the second method, and with the first method the vertical grooves in the paneling will be behind the molding...seeming to make a place for moisture to collect.

Just looking for some tips...before I start nailing!

Last edited: