- #1

crazy_emu

- 5

- 1

I want to install two retractable patio screens on my patio but there aren't any columns, so I'll need to install a post/column to attach the screens and guide rails to. My concern is making sure I install an adequate post for support during winds. If I can avoid it, I'd like to stay away from installing stringers/headers from the corner post to the sides of my home. The housing where the screens roll up are pretty stout; all extruded aluminum, and would be installed from the post to the sides of the house, more or less acting as the stringers/headers.

Initially, I was using a calc for wind load that estimates the force at F = A x P x Cd. The two screens total an area of 468sqft, the Pressure is calculated using 75mph wind and the drag coefficient used is 1.5. This gives a force of 5700 lbft. Though, this assumes all force is perpendicular to the screens and is the total area of both screens combined.

Assuming the force on the screens is accurate, what would be the force transferred to the base plate of the tube steel post, anchors and concrete? I plan to use 1/2" x 5-1/2" Hilti Kwik Bolt anchors with minimum 3.5" embedment. Any help would be appreciated. I'm unsure of how to move forward with evaluating what would be required of the post and anchors to adequately resist wind loads.

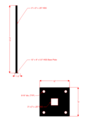

Files attached showing sketches of patio layout, corner post and profile view of the patio screens.

Initially, I was using a calc for wind load that estimates the force at F = A x P x Cd. The two screens total an area of 468sqft, the Pressure is calculated using 75mph wind and the drag coefficient used is 1.5. This gives a force of 5700 lbft. Though, this assumes all force is perpendicular to the screens and is the total area of both screens combined.

Assuming the force on the screens is accurate, what would be the force transferred to the base plate of the tube steel post, anchors and concrete? I plan to use 1/2" x 5-1/2" Hilti Kwik Bolt anchors with minimum 3.5" embedment. Any help would be appreciated. I'm unsure of how to move forward with evaluating what would be required of the post and anchors to adequately resist wind loads.

Files attached showing sketches of patio layout, corner post and profile view of the patio screens.