- #1

mheruian

- 7

- 1

Hello,

I'm boy who suddenly been strucked by curiosity on how hand crank generator works and i watch and read some of how to create one, specially this one on youtube:

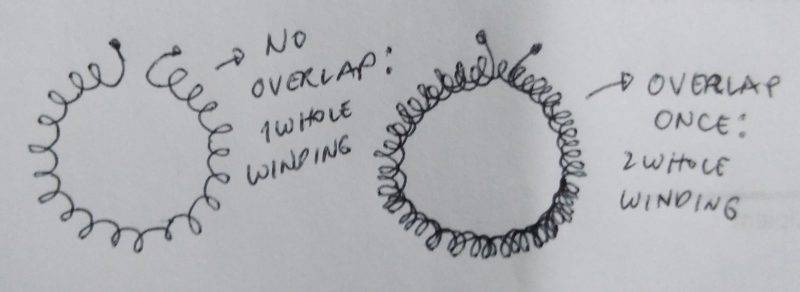

and i want to create one but i don't have a 3D printer, but i saw some alternative but as i do/design my own coil based on what i watched and read, it came to my mind how many winding works. I understand straight-forward winding from left to right but these where the two things that many videos and tutorials didn't mention about:

1) starting left to right then after reaching end of the core, right to left winding

2) starting left to right then after reaching end of the core, jump to left to wind right again

3) starting left to right but before reaching right, a lot of times doing right to left then left to right then right to left and left to right until reaching end of the core.

- doesn't these effect the direction of magnetic field, etc? any drawbacks or setbacks with these?

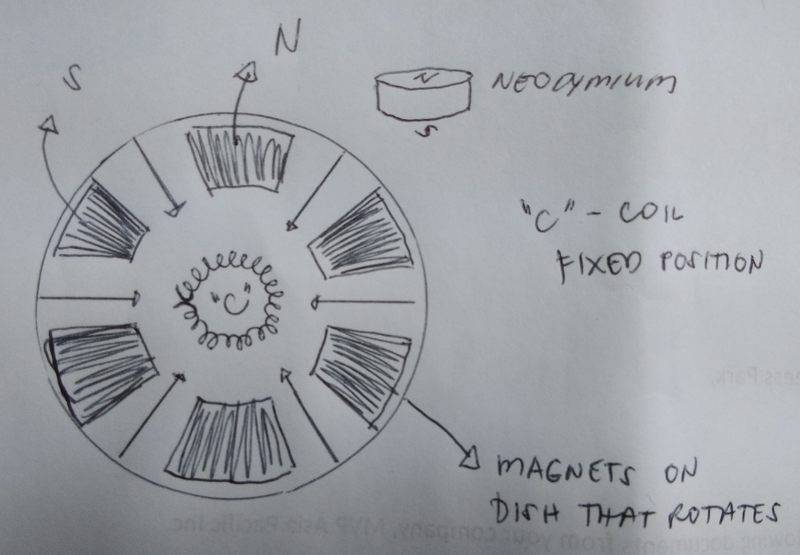

also, images below show what I am doing, please help me if this thing would work or not. No one around here could help me with this kind of stuffs personally

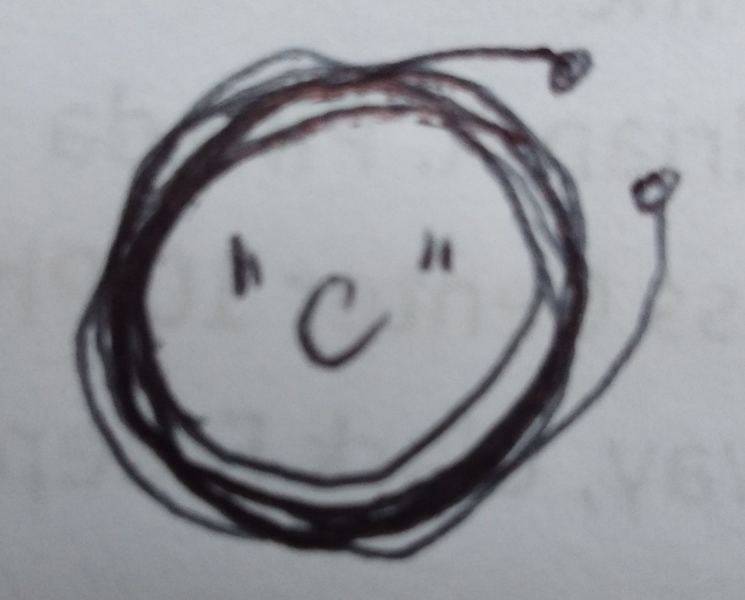

The coil will be like the toroidals so windings will be upright horizontal in circle.

Above where the questions i want to know

And if the image below can be done using coil winded up vertically instead the toroidal

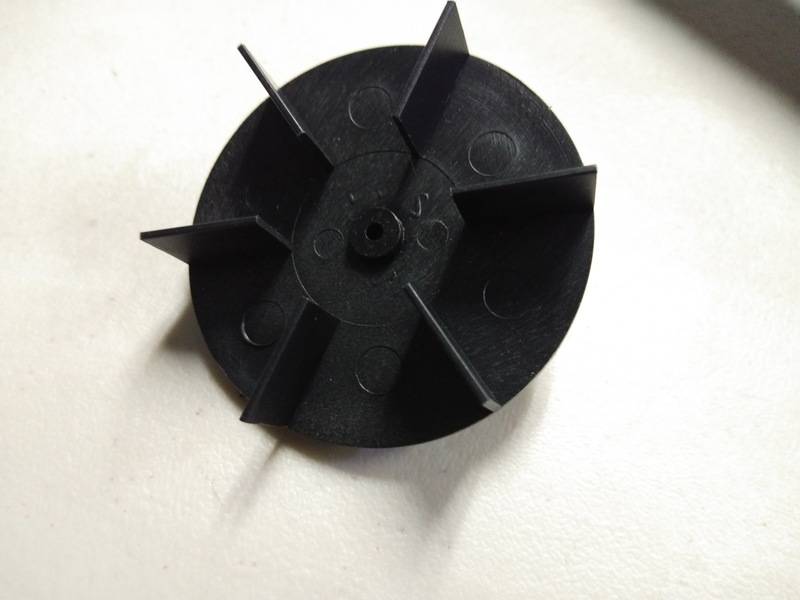

My setup:

where i will place my toroidal winding (2mm plastic core at the center)

Thanks for those who would help I'm not a genius but i want to learn and have fun.

I'm not a genius but i want to learn and have fun.

I'm boy who suddenly been strucked by curiosity on how hand crank generator works and i watch and read some of how to create one, specially this one on youtube:

and i want to create one but i don't have a 3D printer, but i saw some alternative but as i do/design my own coil based on what i watched and read, it came to my mind how many winding works. I understand straight-forward winding from left to right but these where the two things that many videos and tutorials didn't mention about:

1) starting left to right then after reaching end of the core, right to left winding

2) starting left to right then after reaching end of the core, jump to left to wind right again

3) starting left to right but before reaching right, a lot of times doing right to left then left to right then right to left and left to right until reaching end of the core.

- doesn't these effect the direction of magnetic field, etc? any drawbacks or setbacks with these?

also, images below show what I am doing, please help me if this thing would work or not. No one around here could help me with this kind of stuffs personally

The coil will be like the toroidals so windings will be upright horizontal in circle.

Above where the questions i want to know

And if the image below can be done using coil winded up vertically instead the toroidal

My setup:

where i will place my toroidal winding (2mm plastic core at the center)

Thanks for those who would help

I'm not a genius but i want to learn and have fun.

I'm not a genius but i want to learn and have fun.

to light an LED is great but i want it to be a charger in the future like using the super capacitor, bridge rectifiers and charging circuit (android, iphone, etc. 5v devices). I ordered online neodymium magnets that are 10mm in diameter 4mm in height as well the coils so for now so i can't measure its voltage, i am at designing while waiting for my orders. I want t verify first before the items comes up for me to know what to do as much as possible.

to light an LED is great but i want it to be a charger in the future like using the super capacitor, bridge rectifiers and charging circuit (android, iphone, etc. 5v devices). I ordered online neodymium magnets that are 10mm in diameter 4mm in height as well the coils so for now so i can't measure its voltage, i am at designing while waiting for my orders. I want t verify first before the items comes up for me to know what to do as much as possible.