needing

- 6

- 0

Hi.

First post so I hope I have the correct thread location.

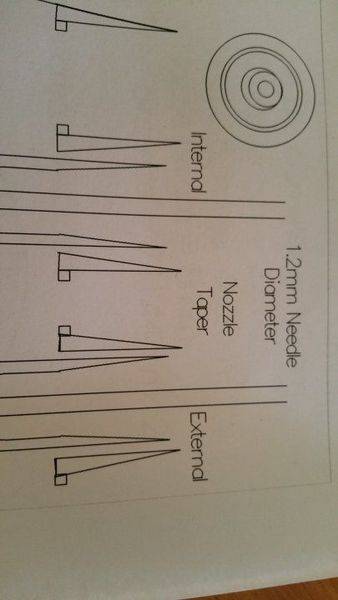

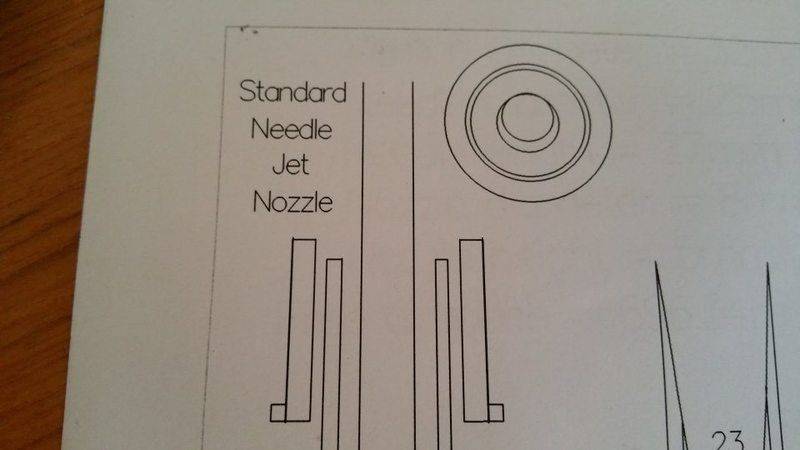

I am reverse engineering a 40+ year old vertical slide carburettor design i.e. the venturi is horizontal. The current spray nozzle protudes vertically into the airflow but is straight sided and flat across the exit.

Option 1.

Internally taper the nozzle (15°included angle) so the metering annulus remained the same near the base but the exit is now as wide as the OD and knife-edged.

Option 2.

Externally taper the nozzle so the metering annulus remained the same for the height of the nozzle, the exit retains the original ID but is now knife-edged.

The question:

Wikl option 1 or 2 improve spray spread and atomisation at the exit for a given airflow? or option 3 : do nothing.

Ta.

Owen.

First post so I hope I have the correct thread location.

I am reverse engineering a 40+ year old vertical slide carburettor design i.e. the venturi is horizontal. The current spray nozzle protudes vertically into the airflow but is straight sided and flat across the exit.

Option 1.

Internally taper the nozzle (15°included angle) so the metering annulus remained the same near the base but the exit is now as wide as the OD and knife-edged.

Option 2.

Externally taper the nozzle so the metering annulus remained the same for the height of the nozzle, the exit retains the original ID but is now knife-edged.

The question:

Wikl option 1 or 2 improve spray spread and atomisation at the exit for a given airflow? or option 3 : do nothing.

Ta.

Owen.