- #1

gmartine

- 4

- 1

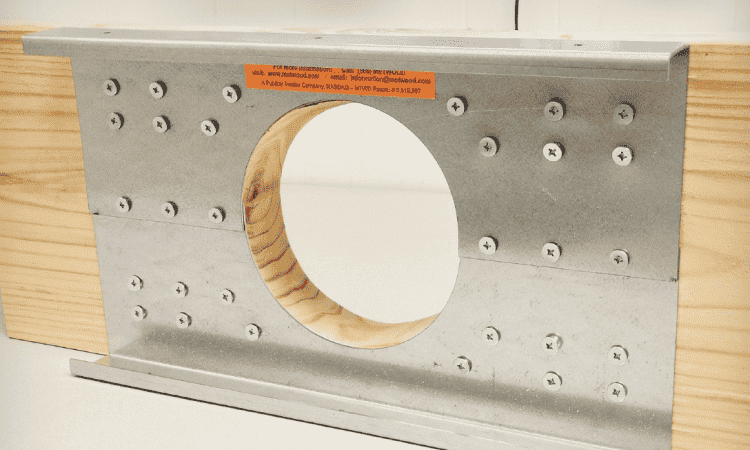

Thanks for taking interest but I studied basic statics about three decades ago and I wasn't quite sure what the definitive answer was...can anybody tell me what the preferred arrangement of this reinforcement bracket should be?

Should it be as shown in the picture to achieve maximum stiffness or with the flanges hooked over and under the joist as the article below suggests. I thought initially the increased area moment of inertia by having the flanges mounted away from the beam would have made a difference? Assume the beam is a 12 x 2" and the hole is 8" diameter, bracketry is standard 14 gauge BMS, thanks again.

https://www.proremodeler.com/innovative-products-metwood-building-solutions-joist-reinforcements

Should it be as shown in the picture to achieve maximum stiffness or with the flanges hooked over and under the joist as the article below suggests. I thought initially the increased area moment of inertia by having the flanges mounted away from the beam would have made a difference? Assume the beam is a 12 x 2" and the hole is 8" diameter, bracketry is standard 14 gauge BMS, thanks again.

https://www.proremodeler.com/innovative-products-metwood-building-solutions-joist-reinforcements