Dirk

- 4

- 0

Hey all,

I want to calculate the force which is needed to cut the blades of a wind turbine in half(for transport reasons). I presume guillotine is the best option due to various reasons. But I don’t know how to calculate the cutting force which is needed for this unique structure and material. The blades material is mostly GFRP (glass fibre reinforced polymer). The width (cutting length) is around 3 meters(variable), the thickness is 20mm(variable).

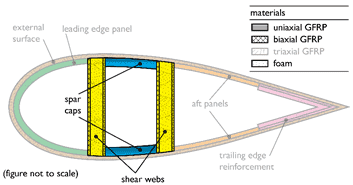

Below a picture of the structure

EDIT: actually I am a bit further in my research and i come to the conclusion that I need to know the interlaminear shear strength value of the material used in windturbine blades. Using this value I can calculate the force needed to cut the material I think. So how do I find this value??

If more information is needed, feel free to ask!

Thanks in advance.

I want to calculate the force which is needed to cut the blades of a wind turbine in half(for transport reasons). I presume guillotine is the best option due to various reasons. But I don’t know how to calculate the cutting force which is needed for this unique structure and material. The blades material is mostly GFRP (glass fibre reinforced polymer). The width (cutting length) is around 3 meters(variable), the thickness is 20mm(variable).

Below a picture of the structure

EDIT: actually I am a bit further in my research and i come to the conclusion that I need to know the interlaminear shear strength value of the material used in windturbine blades. Using this value I can calculate the force needed to cut the material I think. So how do I find this value??

If more information is needed, feel free to ask!

Thanks in advance.

Attachments

Last edited: