- #1

lforster02

- 1

- 0

I am trying to calculate the theoretical thickness of an anodised coating. I know all values apart from I am unsure whether to use 2e or 6e for the amount of electrons.

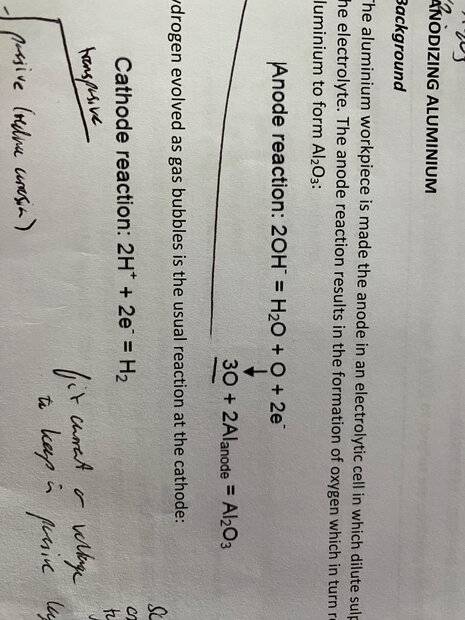

Anode reaction as follows: 2OH = H2O + O + 2e

the aluminium reactions preferentially with the one O atom, using equation: 3O + 2Al (anode) = Al2O3

There is 2 electrons transferred in the anode reaction, although 3O consumed to produce the coating Al2O3, which means 6e is transferred. Does anyone have any idea whether to use 6 or 2 in the formula: thickness = (1/density) x ((molecular mass x current x time) / (area x number of e x faradays constant))

Attached are the relevant reactions

Anode reaction as follows: 2OH = H2O + O + 2e

the aluminium reactions preferentially with the one O atom, using equation: 3O + 2Al (anode) = Al2O3

There is 2 electrons transferred in the anode reaction, although 3O consumed to produce the coating Al2O3, which means 6e is transferred. Does anyone have any idea whether to use 6 or 2 in the formula: thickness = (1/density) x ((molecular mass x current x time) / (area x number of e x faradays constant))

Attached are the relevant reactions

Last edited by a moderator: