Ben_Walker1978

- 113

- 6

- Homework Statement

- Young's Modulus

- Relevant Equations

- e = Stress/Strain

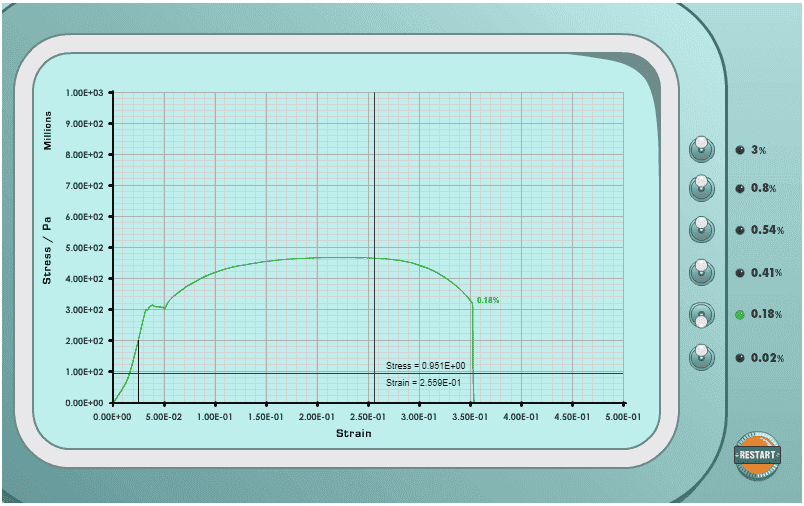

I am trying to calculate Young's Modulus on the graph below.

I have run the test through some software, now want to calculate Young's Modulus to ensure my analysis can be relied upon to be scientifically sound.

This is what i have calculated from learning online. Is this correct? I have 2 more graphs to do after this.

As you can see i have drawn a line in black to calculate, although not sure if it is correct, or in the correct place.

0.18% Mild Steel

My calculations:

Young's Modulus

$$Slope = e /Θ=Stress /Strain =2.00e + 02 / 0.250e − 02 = 200 /0.00250 = 80,000MPa $$Is this correct to calculate Young's Modulus from this graph?

If not where have i gone wrong?

Thomas.

I have run the test through some software, now want to calculate Young's Modulus to ensure my analysis can be relied upon to be scientifically sound.

This is what i have calculated from learning online. Is this correct? I have 2 more graphs to do after this.

As you can see i have drawn a line in black to calculate, although not sure if it is correct, or in the correct place.

0.18% Mild Steel

My calculations:

Young's Modulus

$$Slope = e /Θ=Stress /Strain =2.00e + 02 / 0.250e − 02 = 200 /0.00250 = 80,000MPa $$Is this correct to calculate Young's Modulus from this graph?

If not where have i gone wrong?

Thomas.