SUMMARY

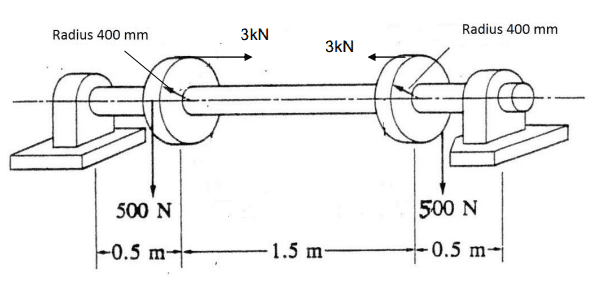

The discussion focuses on calculating the suitable diameter of a circular shaft in a pulley system to prevent failure due to maximum shear stress. Each pulley exerts a tangential force of 500N, and the tensile yield strength of the shaft material is specified as 248MN/m². Using the maximum shear stress criterion, participants detail the steps to derive the necessary shaft diameter, ensuring structural integrity under the applied loads.

PREREQUISITES

- Understanding of shear stress and tensile yield strength

- Knowledge of basic mechanics of materials

- Familiarity with pulley systems and load calculations

- Ability to perform calculations involving circular shaft dimensions

NEXT STEPS

- Research the maximum shear stress criterion in mechanical design

- Learn about the mechanics of materials, focusing on shear and tensile strength

- Explore the design principles for pulley systems and their load distributions

- Study the calculations for determining shaft diameters in various loading conditions

USEFUL FOR

Mechanical engineers, structural designers, and students studying applied mechanics who are involved in the design and analysis of shaft systems in machinery.