vega7

- 1

- 0

Here is a relatively simple problem. I'm wondering if someone can give me their opinion on it or actually know experimentally if it is true.

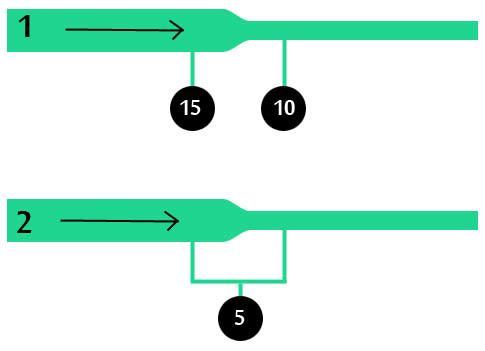

Here is the diagram:

A flow of liquid (say water) is pumped through a pipe that has a reduction in diameter. You place a pressure gauge before and after the reduction to measure the pressure.

In setup 1, you have 15psi before and 10psi after. The pressure differential is 5psi.

Now, here is the part I am not sure about. In setup 2, If you connected a thin tube (as not to disturb system) between both diameters and then placed one gauge. What would that gauge read? Would this setup work?

Would the pressure read the differential pressure of 5psi (as above)? Or, would it just be the average of the pressures 12.5psi? Or, would it read something else?

Has anyone tried this?

Here is the diagram:

A flow of liquid (say water) is pumped through a pipe that has a reduction in diameter. You place a pressure gauge before and after the reduction to measure the pressure.

In setup 1, you have 15psi before and 10psi after. The pressure differential is 5psi.

Now, here is the part I am not sure about. In setup 2, If you connected a thin tube (as not to disturb system) between both diameters and then placed one gauge. What would that gauge read? Would this setup work?

Would the pressure read the differential pressure of 5psi (as above)? Or, would it just be the average of the pressures 12.5psi? Or, would it read something else?

Has anyone tried this?