- #1

shane2

- 89

- 3

I'm needing to reflect additional solar into a greenhouse to increase plant beneficial PAR light (400-700nm) while restricting and minimizing excessive IR heat also building up inside, too.

I'll be using 400 sq ft of flat plate reflectors (40'X10') at ground level horizontally positioned along and outside the southern facing vertical clear poly walls of the greenhouse.

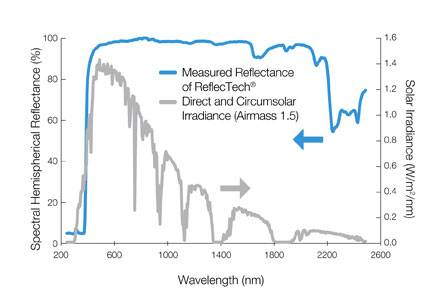

These rigid flat reflector surfaces will be topped with a specular mirror finished poly film, specifically http://www.reflectechsolar.com/technical.html

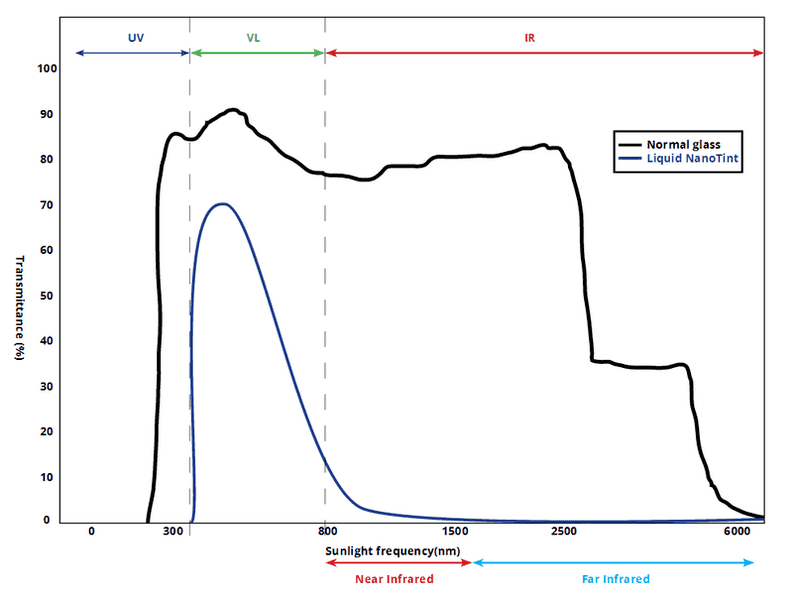

If compatibility tests first confirm no issues (manufacturer said should be OK), I intend to then next topcoat apply onto reflective film this liquid nano IR blocker product here... https://drywired.com/wp-content/uploads/2015/06/Liquid-NanoTint-PDS.pdf

Which claims to block/absorb a significant portion of the NIR and Far IR heat producing portion of the solar spectrum when applied to windows.

My question is, of the light then reflected and exiting this reflective combo, what might specular degradation and transmittance %'s and IR absorption %'s all look like after those incident solar rays had passed through that nano top coating twice?

Is it reasonable to just cut performance values in graph above in half for rough idea of the effect to be expected, or is there likely other and additional effects to also be considered here now? (Besides expecting absorbed IR heat should be greater on treated reflector and its substrate than a window that only gets a single pass.)

Thanks for any comments or thoughts!

- Shane

I'll be using 400 sq ft of flat plate reflectors (40'X10') at ground level horizontally positioned along and outside the southern facing vertical clear poly walls of the greenhouse.

These rigid flat reflector surfaces will be topped with a specular mirror finished poly film, specifically http://www.reflectechsolar.com/technical.html

If compatibility tests first confirm no issues (manufacturer said should be OK), I intend to then next topcoat apply onto reflective film this liquid nano IR blocker product here... https://drywired.com/wp-content/uploads/2015/06/Liquid-NanoTint-PDS.pdf

Which claims to block/absorb a significant portion of the NIR and Far IR heat producing portion of the solar spectrum when applied to windows.

My question is, of the light then reflected and exiting this reflective combo, what might specular degradation and transmittance %'s and IR absorption %'s all look like after those incident solar rays had passed through that nano top coating twice?

Is it reasonable to just cut performance values in graph above in half for rough idea of the effect to be expected, or is there likely other and additional effects to also be considered here now? (Besides expecting absorbed IR heat should be greater on treated reflector and its substrate than a window that only gets a single pass.)

Thanks for any comments or thoughts!

- Shane