Artonn

- 5

- 0

I'm not sure if this is the right thread to post this, but here it is!

I'm currently trying to create a prop for one of my friends, since I found it an interesting challenge.

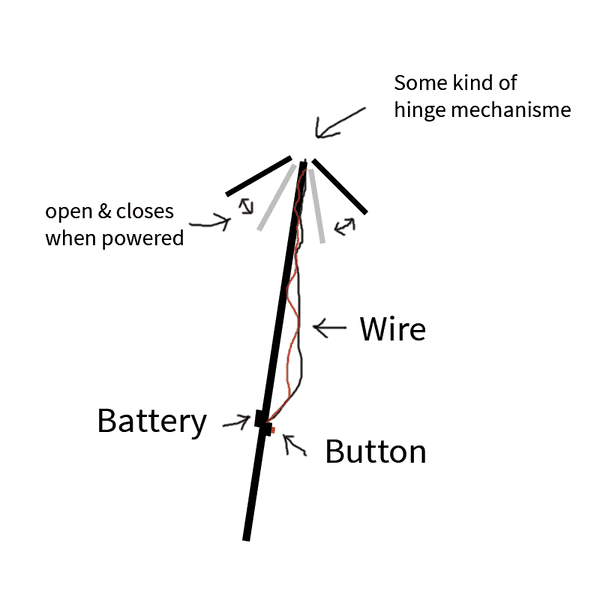

This is a simple drawing of what I'm trying to do:

The button, battery and so on it not my problem, it's that I've no idea how to create this hinge mechanisme I want. As demonstrated I basically want to make something that can push a light tube up in a straight line when powered, there's going to be three of them where each one of them should have one of these hinge mechanisme. Feel freely to ask me more questions about my project, since I'm beginner and not sure where to start with anything regarding the hinge mechanisme. Thanks. :)

I'm currently trying to create a prop for one of my friends, since I found it an interesting challenge.

This is a simple drawing of what I'm trying to do:

The button, battery and so on it not my problem, it's that I've no idea how to create this hinge mechanisme I want. As demonstrated I basically want to make something that can push a light tube up in a straight line when powered, there's going to be three of them where each one of them should have one of these hinge mechanisme. Feel freely to ask me more questions about my project, since I'm beginner and not sure where to start with anything regarding the hinge mechanisme. Thanks. :)