SUMMARY

Induction heating of a coiled spring, specifically a spiral spring with a diameter of approximately 300mm and a wire gauge of around 1mm, is feasible but presents challenges. For effective induction heating, the spring must be electrically connected at both ends, and an AC field must couple directly into the coil. However, heating the spring evenly is problematic, as evidenced by past experiences where induction heating failed to uniformly heat bearings, leading to the recommendation of using an oven instead. For optimal heating solutions, consulting specialized heater manufacturers like Omega Engineering is advised.

PREREQUISITES

- Understanding of induction heating principles and eddy currents

- Knowledge of AC electrical fields and their interaction with metal

- Familiarity with heating methods for metal components

- Basic concepts of thermal expansion and material tempering

NEXT STEPS

- Research the principles of induction heating and eddy current generation

- Explore the specifications and applications of Omega Engineering heating solutions

- Learn about the design and operation of heating elements for industrial applications

- Investigate the effects of thermal treatment on metal properties, particularly tempering

USEFUL FOR

Engineers, metalworking professionals, and anyone involved in the design and application of heating systems for metal components, particularly those considering induction heating for complex shapes like springs.

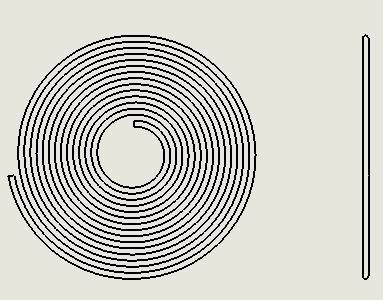

If I had a spirally coiled spring like inserted pic, spiral coiled spring approx. 300mm dia and spring section +-12mm dia with +-1mm gauge wire, with a total length of spring approx. 4mtr-6mtr , is it possible to heat this with induction heating generator, say similar to an induction geyser system? would the coil heat up evenly, if possible? can it be heated from one side of the coil or would you need 2 induction elements one either side or is it just not possible? any assistance with clearing this up will be appreciated.

If I had a spirally coiled spring like inserted pic, spiral coiled spring approx. 300mm dia and spring section +-12mm dia with +-1mm gauge wire, with a total length of spring approx. 4mtr-6mtr , is it possible to heat this with induction heating generator, say similar to an induction geyser system? would the coil heat up evenly, if possible? can it be heated from one side of the coil or would you need 2 induction elements one either side or is it just not possible? any assistance with clearing this up will be appreciated.