- #1

Vatech

- 54

- 7

- TL;DR Summary

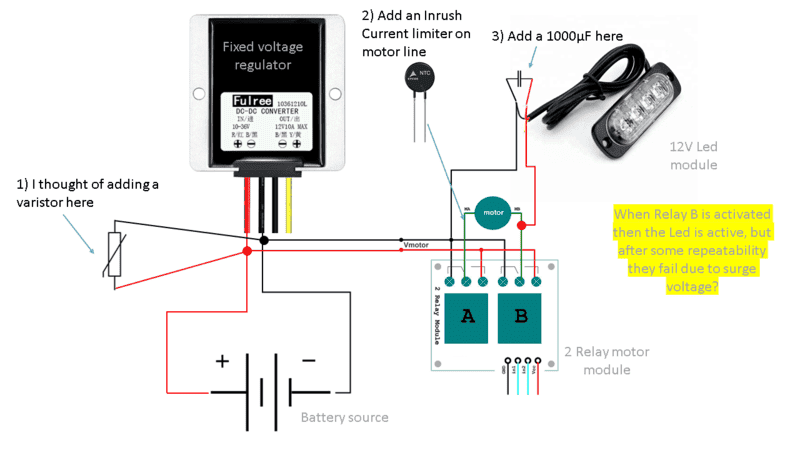

- A led module gets damaged. Surge Voltage ? Inrush current or am i missing something?

I use a 2 Relay Motor module to control Direction on a motor (linear actuator). When Relay A is active, actuator retracts. When Relay B is active, actuator extents and Led Module is activated. After some repetitions Led module fail.

Cause of the fail?

I believe Surge voltage, although i am not an expert on electronics. Inrush current or instant voltage drop due to high load could also be the reason.

Maybe i am missing something on Relay connection

Please excuse me for the rough presentation, but will help enough to give you a visual perspective of the problem.

Thank you in advance for your suggestions.

Cause of the fail?

I believe Surge voltage, although i am not an expert on electronics. Inrush current or instant voltage drop due to high load could also be the reason.

Maybe i am missing something on Relay connection

Please excuse me for the rough presentation, but will help enough to give you a visual perspective of the problem.

Thank you in advance for your suggestions.