Marinovich91

- 6

- 1

Greetings to everyone,

Recently I bought sailboat with rudder which is actuated by hydraulic oil by cylnder and pump at steering wheel.

I have been trying to calculate steering effort(feedback) on my hydraulic operated sailboat if I change my current cylnder,but nusucessfully.

Problem is that with my current specs I don't need to use any effort to stear the boat and there are too many turns(6) on 70cm diameter steering wheel.

With sailboat it is necesary to have effort when sailing, and to achieve this I need to downsize the cylnder which is connected directly to rudder over tiller arm 18.But downsizeing cylnder I am increasing effort, but I don't want to be in situation to use both my hands to steer.

As well on my steering wheel is connected my autopilot which can't handle more than 5Nm of force, so before buying anything I decided to make calculation,to know by how much and how effort is changed.

In order to calculate approximation (+- 200 grams) found couple of formulas and putted them down in excell sheet down below, for each rudder angle of attack(different drag force), necesary tiller arm and different speed(since speed drops automaticly when you steer trough water).

As you can see firstly I was calculateing force of drag for each angle of attack, and than transvered forces to hydraulic cylnder, and than moment on pump shaft.

Problem comes when I try to calculate drive power of pump in wats and put it Newton-meters per second...all goes wrong.At this point I am not sure what I am doing wrong.

For example I get,

I need to use 0,06kg/s on my steering wheel for 3 seconds to achive feedback of ruder at the end of 3 seconds of 0,54kg... but 0.06+0.06+0.06=0.18kg

If anyone can help me I would be grateful.

In attachment you can find excel sheet of all calculations, which includes 3 cylnders with different angles of attack, but it is same formula for all rows.

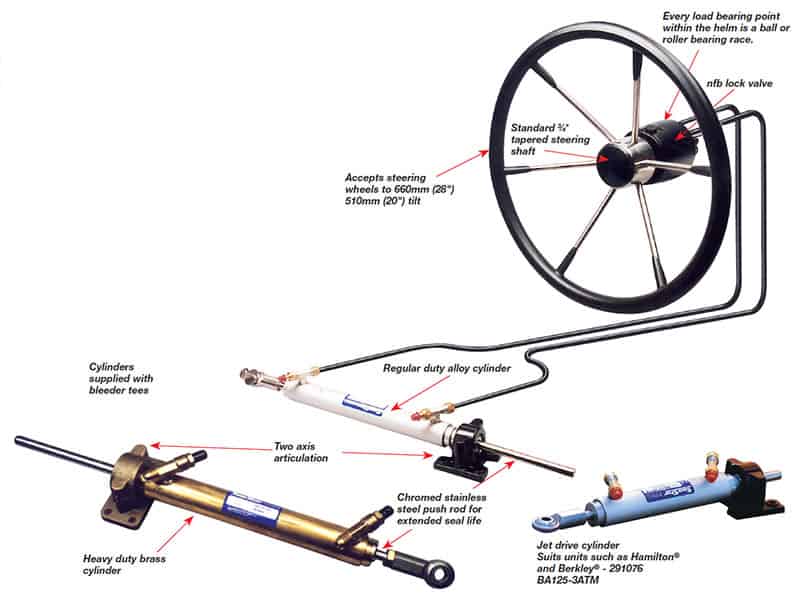

Below are related images of system.

System overview

Rudder transformation to calculate how much rudder is balanced and effective drag area

Rudder transformation to calculate how much rudder is balanced and effective drag area

Drag coeficient trend

Current cylnder

P.S.

P.S.

It may be important to say that rudder is hydrofoil shaped

Can anyone confirm I used correct formulas for calculation of steering effort

P=(p*Q)/(600*n1)= (watt)

Recently I bought sailboat with rudder which is actuated by hydraulic oil by cylnder and pump at steering wheel.

I have been trying to calculate steering effort(feedback) on my hydraulic operated sailboat if I change my current cylnder,but nusucessfully.

Problem is that with my current specs I don't need to use any effort to stear the boat and there are too many turns(6) on 70cm diameter steering wheel.

With sailboat it is necesary to have effort when sailing, and to achieve this I need to downsize the cylnder which is connected directly to rudder over tiller arm 18.But downsizeing cylnder I am increasing effort, but I don't want to be in situation to use both my hands to steer.

As well on my steering wheel is connected my autopilot which can't handle more than 5Nm of force, so before buying anything I decided to make calculation,to know by how much and how effort is changed.

In order to calculate approximation (+- 200 grams) found couple of formulas and putted them down in excell sheet down below, for each rudder angle of attack(different drag force), necesary tiller arm and different speed(since speed drops automaticly when you steer trough water).

As you can see firstly I was calculateing force of drag for each angle of attack, and than transvered forces to hydraulic cylnder, and than moment on pump shaft.

Problem comes when I try to calculate drive power of pump in wats and put it Newton-meters per second...all goes wrong.At this point I am not sure what I am doing wrong.

For example I get,

I need to use 0,06kg/s on my steering wheel for 3 seconds to achive feedback of ruder at the end of 3 seconds of 0,54kg... but 0.06+0.06+0.06=0.18kg

If anyone can help me I would be grateful.

In attachment you can find excel sheet of all calculations, which includes 3 cylnders with different angles of attack, but it is same formula for all rows.

Below are related images of system.

System overview

Drag coeficient trend

Current cylnder

It may be important to say that rudder is hydrofoil shaped

Can anyone confirm I used correct formulas for calculation of steering effort

P=(p*Q)/(600*n1)= (watt)

Attachments

Last edited: