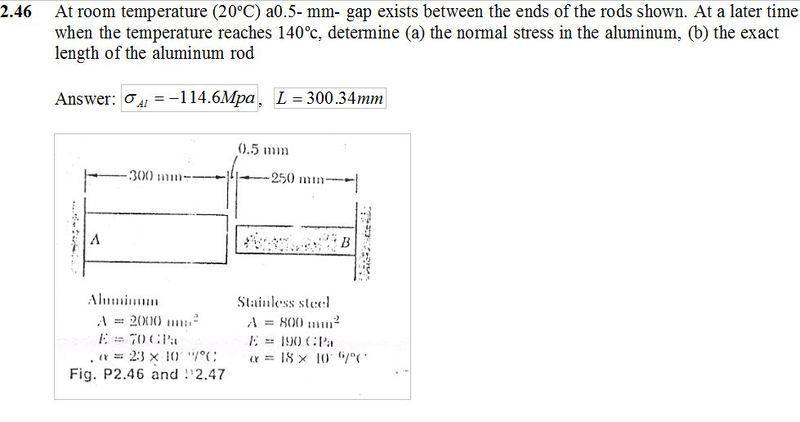

- #1

Dell

- 590

- 0

in the following problem

i know that ΔT=120

now the maximum deflection is 0.5mm so i looked for the total deflection had there been no restrictions

ΔL(aluminium)=300*(23e-6*120)= 0.8280

ΔL(st steel)=250*(18e-6*120)= 0.5400

this is clearly more than the maximum deflection of 0.5- there are 0.868 "extra" which cause the stress.

now putting this all together is where i get stumped.

F=ε*E*A

and ΔL=ε*L

F(aluminium)=ε(al)*(70e9)*(2000)

F(steel)=ε(s)*(190e9)*(800)

ε(al)*300+ε(s)*250=0.5

now the force in the aluminium and in the steel must be equal so i have 3 equation system to solve, after solving i get

F= 1.3201e+011

ε(al)= 0.942928e-3

ε(s)=0.868486e-3

now simply using

σ=ε*E or σ=F/A

σ=ε*E

=0.942928e-3*70e9

=66004960

but the correct answer is -114.6MPa

i can see where this might be wrong, nowhere in my stress calculations do i take into account the amount that each material expands. but i have no idea how to fix it

i know that ΔT=120

now the maximum deflection is 0.5mm so i looked for the total deflection had there been no restrictions

ΔL(aluminium)=300*(23e-6*120)= 0.8280

ΔL(st steel)=250*(18e-6*120)= 0.5400

this is clearly more than the maximum deflection of 0.5- there are 0.868 "extra" which cause the stress.

now putting this all together is where i get stumped.

F=ε*E*A

and ΔL=ε*L

F(aluminium)=ε(al)*(70e9)*(2000)

F(steel)=ε(s)*(190e9)*(800)

ε(al)*300+ε(s)*250=0.5

now the force in the aluminium and in the steel must be equal so i have 3 equation system to solve, after solving i get

F= 1.3201e+011

ε(al)= 0.942928e-3

ε(s)=0.868486e-3

now simply using

σ=ε*E or σ=F/A

σ=ε*E

=0.942928e-3*70e9

=66004960

but the correct answer is -114.6MPa

i can see where this might be wrong, nowhere in my stress calculations do i take into account the amount that each material expands. but i have no idea how to fix it