Tylercc

- 27

- 2

I doing an experiment that involves thermal penetration of copper. Please advise me where to post if I choose the wrong spot. This experiment is being done with what I have on hand and my ability to work the materials.

Materials

2.75 gal pot of water

6qt pressure cooker

100+lb of stripped copper wire that is .81''(2.05mm) in diameter

1 120 volt ac fan

specs

4.5 diameter

Airflow: 110 CFM

2600RPM

stove with 1250 watt burners

Ability to work materials

I can not recirculate the water

I can not melt the copper wire into a shape

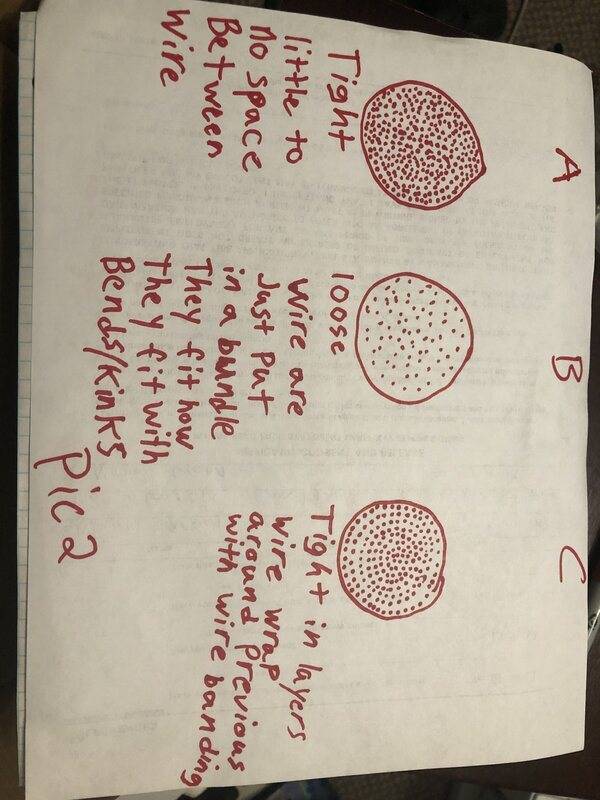

I can tightly or loosely bundle the wire together

I can vary the amount heat introduced into the pressure cooker

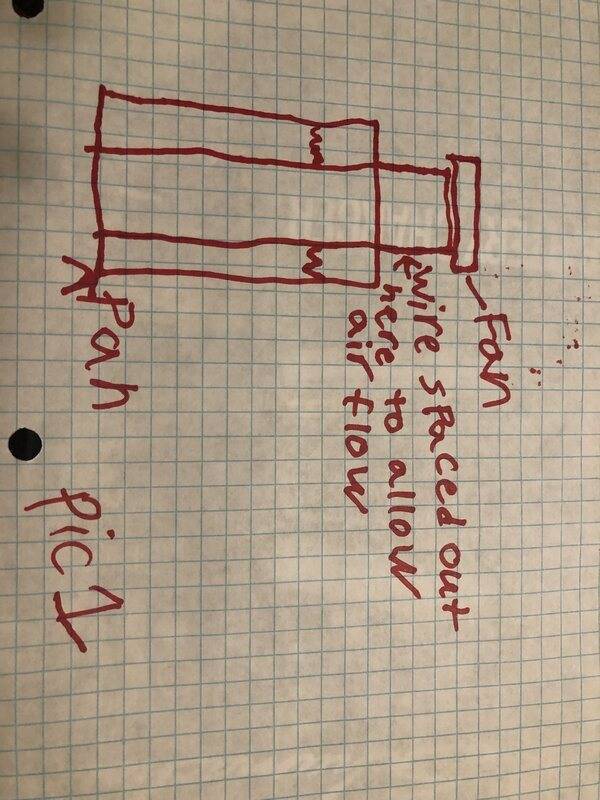

I have a pot of water(2.75gal) that is being heated by steam at a rate of 25 degrees every 15 minutes at "high". The water starts out at 73 degrees F. I would like to cool this water using a bundle of copper wire and a fan on top(pic 1). I am not concerned about how fast I cool the water, but I would like to see the water stay as cool as possible for as long as possible.(EX: 100 degrees F for two hours) So my question is regarding the bundle of wire, Should I make it as tight as possible, as loose as possible, or tight layers with space in-between the layers?(pic2) Also would there be any benefit to making the bundle bigger than the fan?

I have found these two websites but I honestly don't know how to use the equation or if the number in the second webpage is what I need.

https://www.sciencedirect.com/topics/engineering/thermal-penetration-depth

http://hyperphysics.phy-astr.gsu.edu/hbase/Tables/thrcn.html

thanks

Materials

2.75 gal pot of water

6qt pressure cooker

100+lb of stripped copper wire that is .81''(2.05mm) in diameter

1 120 volt ac fan

specs

4.5 diameter

Airflow: 110 CFM

2600RPM

stove with 1250 watt burners

Ability to work materials

I can not recirculate the water

I can not melt the copper wire into a shape

I can tightly or loosely bundle the wire together

I can vary the amount heat introduced into the pressure cooker

I have a pot of water(2.75gal) that is being heated by steam at a rate of 25 degrees every 15 minutes at "high". The water starts out at 73 degrees F. I would like to cool this water using a bundle of copper wire and a fan on top(pic 1). I am not concerned about how fast I cool the water, but I would like to see the water stay as cool as possible for as long as possible.(EX: 100 degrees F for two hours) So my question is regarding the bundle of wire, Should I make it as tight as possible, as loose as possible, or tight layers with space in-between the layers?(pic2) Also would there be any benefit to making the bundle bigger than the fan?

I have found these two websites but I honestly don't know how to use the equation or if the number in the second webpage is what I need.

https://www.sciencedirect.com/topics/engineering/thermal-penetration-depth

http://hyperphysics.phy-astr.gsu.edu/hbase/Tables/thrcn.html

thanks