Lessnan

- 1

- 0

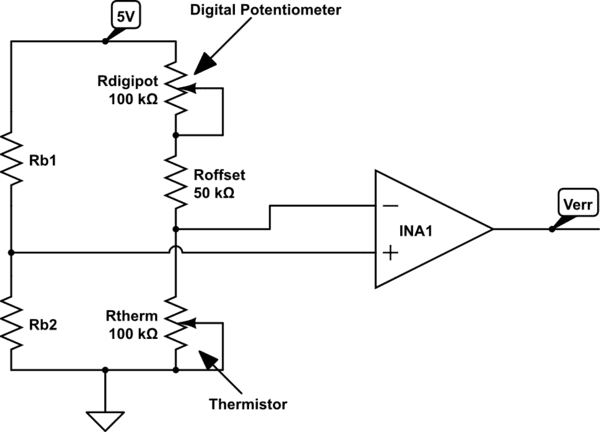

I am currently using a Wheatstone bridge to determine the resistance of a NTC thermistor(Futher information about thermistor: http://www.apogeeweb.net/article/38.html) and feed the difference to the setpoint (analog potentiometer) as the error signal to a PID controller, giving me a way to stabilize the temperature of a sample in conjunction with a TEC to a very good degree.

Now, I'd like to have a way to instead control the setpoint digitally using a microcontroller. The first way I thought of was to simply replace the analog potentiometer by a digital one:

However, the selection of suitable digital potentiometers (able to have 5V at one terminal and possibly a small, negative one at the other) is quite limited and the best one I could find (AD5292) has a temperature coefficient of ~30ppm/K, which is very high for the required accuracy. Additionally, the Digipot gives me a setpoint resolution of ~0.02°C, which I'd like to push down to 0.01°C.

What do you guys think of instead replacing the potentiometer by a fixed resistor, and comparing the voltage after the INA with the output of a DAC and using this difference as the error signal for the PID loop? Would this give me the best performance? (Noise/Stability of this circuit is required to be on the order of milli-Kelvins or even less)

Now, I'd like to have a way to instead control the setpoint digitally using a microcontroller. The first way I thought of was to simply replace the analog potentiometer by a digital one:

However, the selection of suitable digital potentiometers (able to have 5V at one terminal and possibly a small, negative one at the other) is quite limited and the best one I could find (AD5292) has a temperature coefficient of ~30ppm/K, which is very high for the required accuracy. Additionally, the Digipot gives me a setpoint resolution of ~0.02°C, which I'd like to push down to 0.01°C.

What do you guys think of instead replacing the potentiometer by a fixed resistor, and comparing the voltage after the INA with the output of a DAC and using this difference as the error signal for the PID loop? Would this give me the best performance? (Noise/Stability of this circuit is required to be on the order of milli-Kelvins or even less)