Quentin_alex

- 11

- 0

Hello,

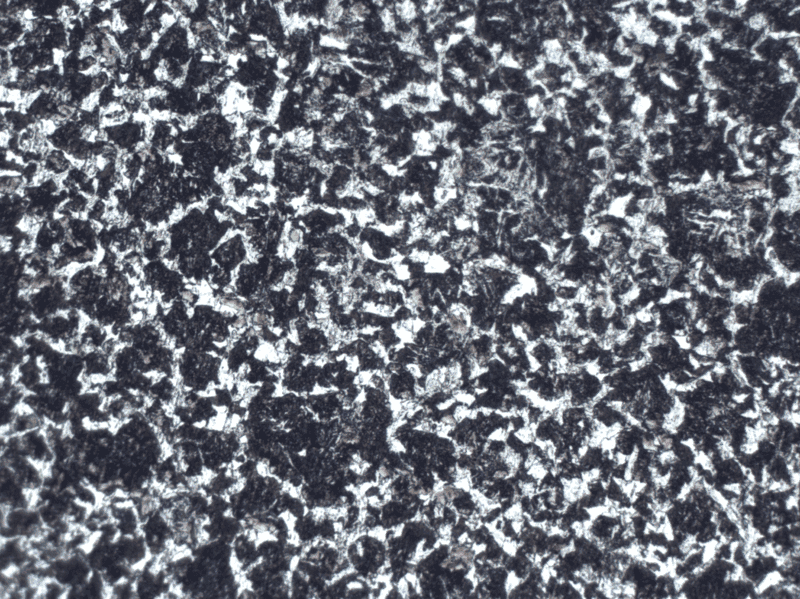

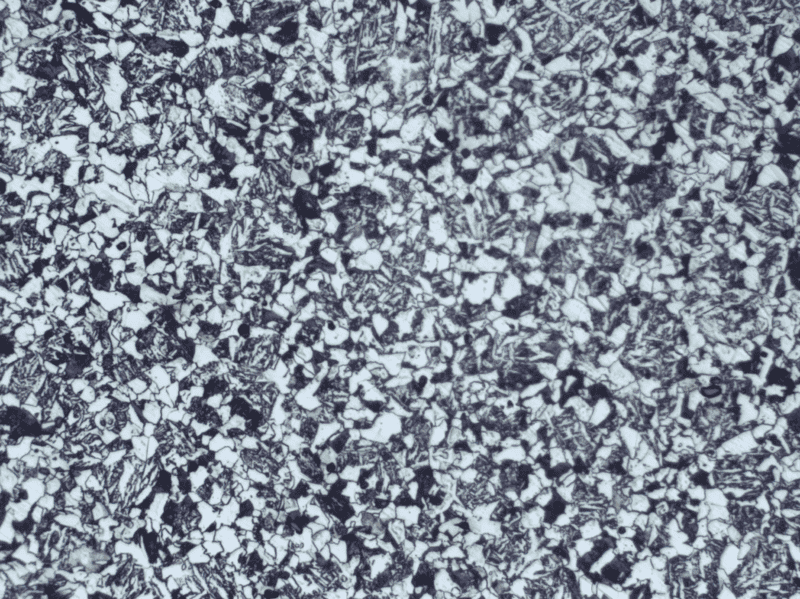

I have two rebar samples of virtually identical chemical composition of 0.27 wt%C, 1.2 wt%Mn and 0.033 wt%V that are A706 grade. The rolling mill parameters are essentially the same yet I am seeing differences in pearlite size upon microscopy. The billets used to make the bars are reheated in a furnace before they hit the mill. What are some possible explanations of why this is occurring?

Attached are the two micrographs taken at the same magnification.

I have two rebar samples of virtually identical chemical composition of 0.27 wt%C, 1.2 wt%Mn and 0.033 wt%V that are A706 grade. The rolling mill parameters are essentially the same yet I am seeing differences in pearlite size upon microscopy. The billets used to make the bars are reheated in a furnace before they hit the mill. What are some possible explanations of why this is occurring?

Attached are the two micrographs taken at the same magnification.