Discussion Overview

The discussion revolves around the comparison of exit velocities predicted by the Hagen-Poiseuille equation and Bernoulli's principle in the context of fluid flow through a nozzle connected to a high-pressure syringe. Participants explore the implications of laminar versus turbulent flow, the role of viscosity, and the effects of pressure loss in a tube.

Discussion Character

- Debate/contested

- Technical explanation

- Mathematical reasoning

Main Points Raised

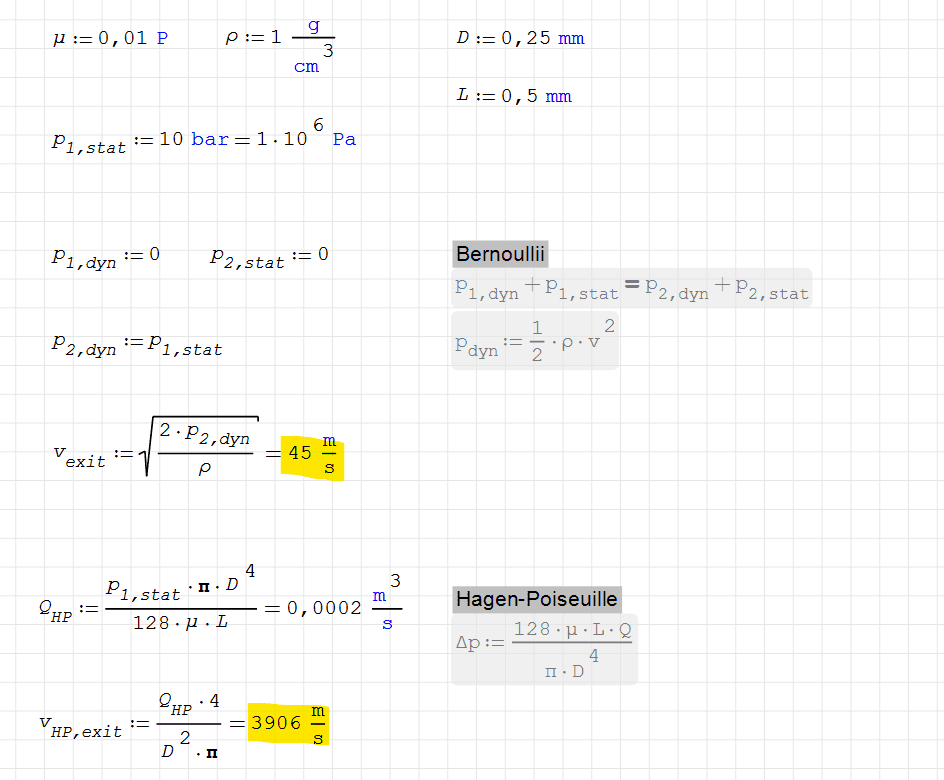

- One participant questions why Hagen-Poiseuille predicts a higher exit velocity than Bernoulli, considering Hagen-Poiseuille accounts for viscosity.

- Another participant notes that Hagen-Poiseuille applies to laminar flow and suggests checking the Reynolds number.

- A participant points out that the Hagen-Poiseuille computation assumes constant velocity, while Bernoulli's computation considers acceleration from rest to a specified speed.

- One participant reports extreme values from their Hagen-Poiseuille calculations and discusses the need for a combination of both equations, while also mentioning the importance of checking the Reynolds number.

- Concerns are raised about the accuracy of calculations, with one participant admitting to a mistake in unit conversion.

- Another participant discusses using the Darcy-Weisbach equation to estimate pressure loss and iterating this into their Bernoulli speed calculation, questioning the validity of their resulting exit velocity.

- Participants clarify that Hagen-Poiseuille assumes laminar flow, while Bernoulli assumes inviscid flow, leading to different implications for the flow regime.

- One participant suggests using a version of Bernoulli's equation that includes frictional energy dissipation, emphasizing the significance of pressure drop in the tube.

- Another participant shares their methodology for estimating pressure drop and velocity, indicating a transition from theoretical predictions to practical calculations.

Areas of Agreement / Disagreement

Participants express differing views on the applicability of Hagen-Poiseuille and Bernoulli's equations under the conditions described, with no consensus reached on the correct approach or the implications of their calculations.

Contextual Notes

Participants highlight the importance of flow regime (laminar vs. turbulent) and the need to consider frictional losses in their calculations. There are indications of potential inaccuracies in initial assumptions and calculations, particularly regarding pressure loss and velocity estimations.

!

!