Discussion Overview

The discussion centers around the relationship between minor principal stress and von Mises stress in the context of failure theories for ductile materials. Participants explore the implications of increasing minor principal stress on von Mises stress, particularly in a plane stress condition without shear stress, and seek an intuitive understanding of this phenomenon.

Discussion Character

- Technical explanation, Conceptual clarification, Debate/contested

Main Points Raised

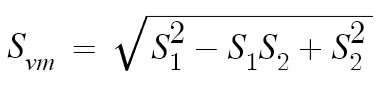

- One participant presents the calculation of von Mises stress, noting that increasing the minor principal stress from 0 to 500 decreases the von Mises stress from 1000 to 866, and asks for an intuitive understanding of this effect.

- Another participant explains that von Mises stress is a measure of shear, which depends on the differences between principal stresses, emphasizing that the third principal stress is zero.

- A later reply reiterates the importance of the differences in principal stresses in relation to the failure of ductile metals, suggesting that this understanding is somewhat intuitive.

- One participant introduces a video on failure theories, discussing the distinction between shear stress and hydrostatic pressure in relation to material failure, and critiques the presentation of these concepts as established facts in textbooks.

- This participant also shares a link to additional information regarding hydrostatic pressure and failure modes, indicating a broader context for understanding these phenomena.

Areas of Agreement / Disagreement

Participants express varying levels of understanding and intuition regarding the relationship between minor principal stress and von Mises stress. There is no consensus on the underlying reasons for the observed behavior, and the discussion includes both technical explanations and critiques of educational approaches.

Contextual Notes

Some participants note the lack of underlying reasons for why shear stress leads to failure in ductile materials while hydrostatic pressure does not contribute, suggesting that these details are often omitted in educational contexts.