- #1

Ben_Walker1978

- 113

- 6

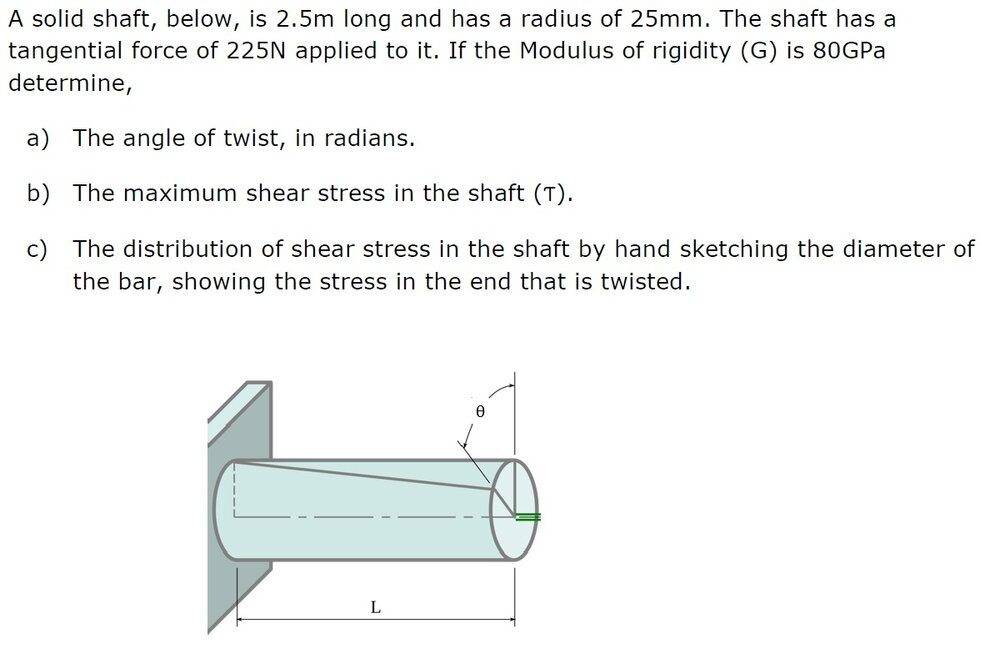

- Homework Statement

- Find the Angle of twist and Shear stress in a shaft

- Relevant Equations

- Angle of twist and Shear stress in a shaft

Hello,

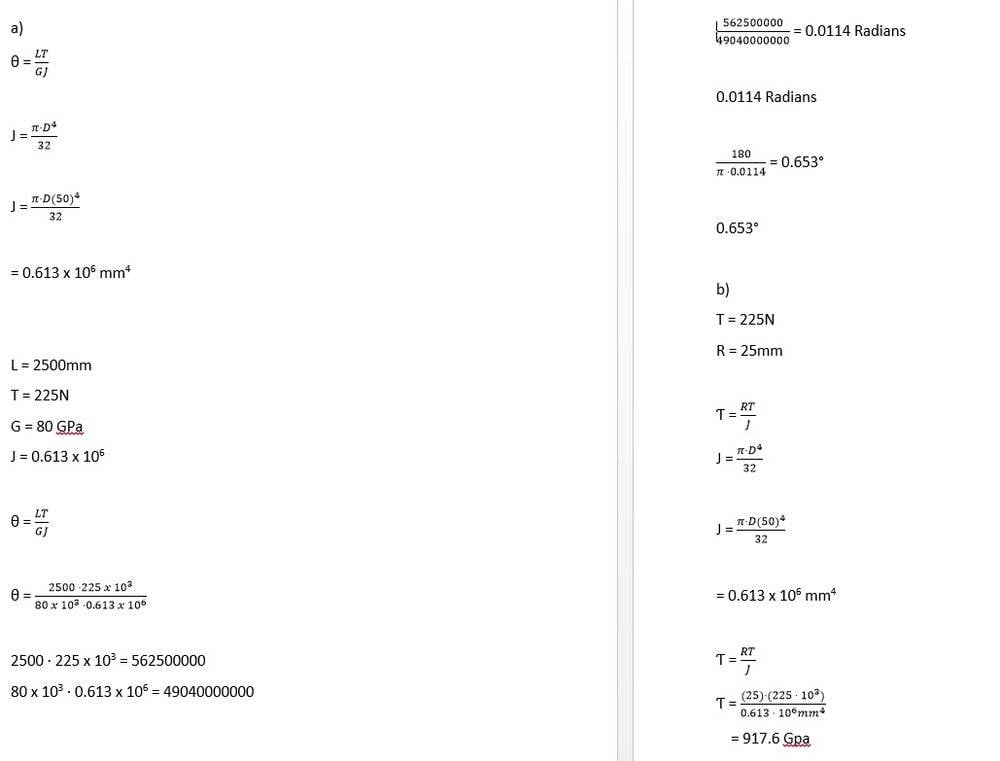

I have attempted the question below.

I think i have correctly completed the question.

Could anyone see if i have gone wrong?

As trying to learn this.

I am just worried about the units m to mm. Also the answer being correct, 917.6Gpa. I was unsure what units to use on the answer.

Question:

Answer:

Answer:

Any help much appreciated.

I have attempted the question below.

I think i have correctly completed the question.

Could anyone see if i have gone wrong?

As trying to learn this.

I am just worried about the units m to mm. Also the answer being correct, 917.6Gpa. I was unsure what units to use on the answer.

Question:

Any help much appreciated.